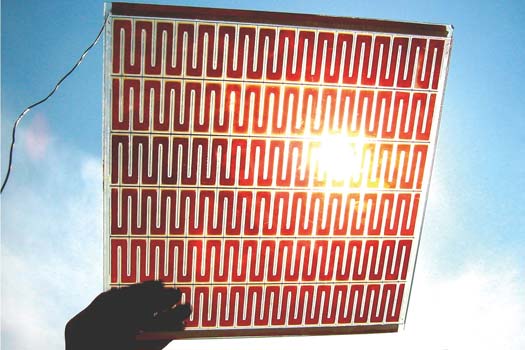

Large-area photovoltaic systems integrated into buildings (BIPVs) are highly promising for sustainable energy generation.

In order for the photovoltaic modules to have a long service life it is essential that they are protected against moisture. The installation of such modules on flat industrial roofs and non-flat surfaces also requires that high-barrier films replace the glass that is currently used for the encapsulation. Films have a lower weight than glass and moreover are also flexible.

The flex25 research project is being undertaken by three Fraunhofer institutes, namely the Fraunhofer Institute for Process Engineering and Packaging IVV, the Fraunhofer Institute for Electron Beam and Plasma Technology FEP, and the Fraunhofer Institute for Silicate Research ISC. The institutes have already developed a barrier film having an extremely low water vapor transmission of 2 x 10-4 g×m-2×d -1 (at 38°C, 90% r.h.). The film comprises a PET substrate onto which inorganic (e.g. AlOx or ZnSnxOy) and hybrid polymer (ORMOCER®) barrier layers are applied by magnetron sputtering or deposited from the liquid phase.

The goal of the flex25 project is to optimize this film system for its stability to UV radiation and weathering. A service life of 25 years is targeted for building-integrated photovoltaic systems (BIPVs). There is thus a need for significant improvement in the radiation and weathering stability of the currently used polymer substrate and barrier layers. In addition, the photovoltaic modules can only utilize the incident solar energy if the barrier film has sufficiently high optical transparency and this thus puts high demands on the coating process.

The research work at Fraunhofer IVV is focusing on the substrate film. Besides needing to be transparent and have good climate stability, this also must have good dimensional stability when subjected to thermal and mechanical loads. High-quality barrier layers can then be applied to this substrate film in order to achieve the desired long service life of the encapsulated photovoltaic modules. For the film system to be economically viable on an industrial scale, all barrier layers will be applied using roll-to-roll processes.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV