The heat contact sealing is one of the most common methods for joining flexible plastic composites. This involves using usually permanently heated tools to melt the thermoplastic layers of thin films and joining them at high machine processing speeds. The films are getting ever thinner and machine speeds ever higher. The requirements on the tightness and optical appearance of the seals are also increasing.

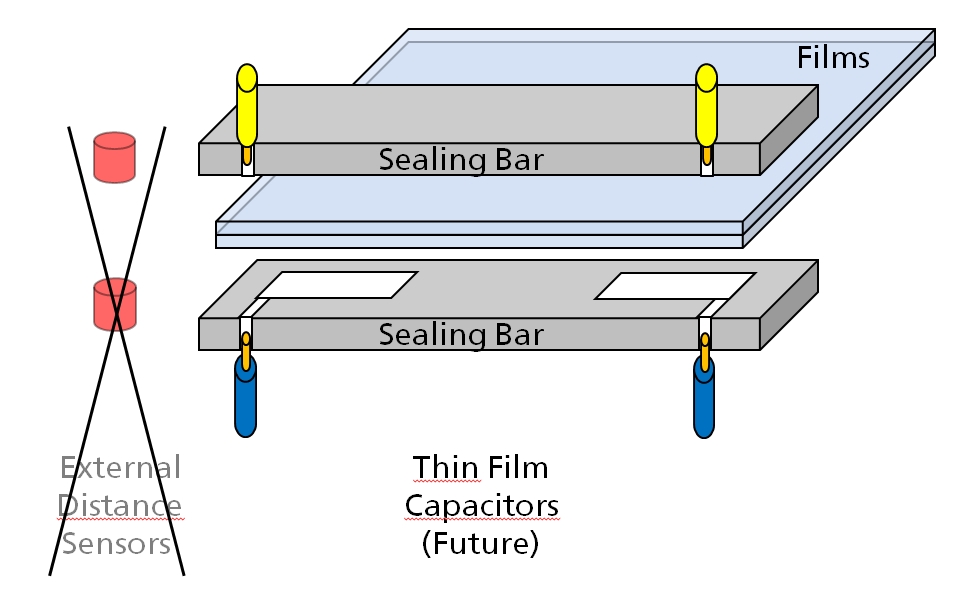

Compared to, for example, ultrasonic sealing, there is currently little ability in heat contact sealing for exact, highly dynamic in-line measurement and evaluation of process parameters. The way that the sealing bar sinks into the film material (tool movement)is a key parameter for assessing melt displacement as a prerequisite for high seal quality, in particular for managing the issue of layer steps. The guaranteeing of stable process conditions also requires the exact alignment of the sealing tool parts to each other. This is usually difficult and can be affected by contaminations. Distance measurement is hence vital for efficient, reliable tool adjustment and for the timely detection of wear or seal contamination.

This research project will investigate the feasibility of such distance measurement using thin film sensors on the sealing tool surface. The work will be undertaken in collaboration with the Fraunhofer Institute for Mechanics of Materials IWM who will develop the measuring principle and manufacture the thin films sensors. The Fraunhofer IVV Dresden will build a prototype with a suitable measuring system and will evaluate detection by the system (measuring range, resolution, suitability) in a series of tests.

The technology being developed will allow improved process monitoring, control, and operation for heat contac sealing. The technology will also be able to be employed for other hot and cold joining methods. It additionally has the potential for contactless, spatially resolved measurement of the film thickness in association with continuous measurement of the web tension distribution.

Weitere Projektinformationen

| Project term: | 2017 |

| Project management /project funding: |

Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. (IVLV) |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV