Mobile Cleaning Device

Automated cleaning of plants and production environments

To address the quality risks associated with manual cleaning processes and the challenges posed by the increasing shortage of skilled workers, a modular, industry-ready technology solution for automating manual cleaning has been developed at the Fraunhofer IVV.

Automated, flexible cleaning of internal and external surfaces

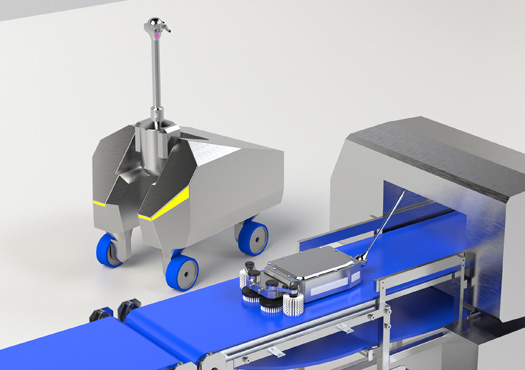

The innovative, fully automated spray cleaning robots were designed for hygiene-critical production environments such as the food industry and revolutionize the concept of flexible and automated cleaning and hygiene of processing facilities.

While the self-driven Exo-MCD enables cleaning of external surfaces of machines and equipment as well as floors, walls, and ceilings in production environments, the Inline-MCD adds a device for in-machine cleaning via the product path (e. g. via conveyor belts or rails).

Efficient, on-demand cleaning processes

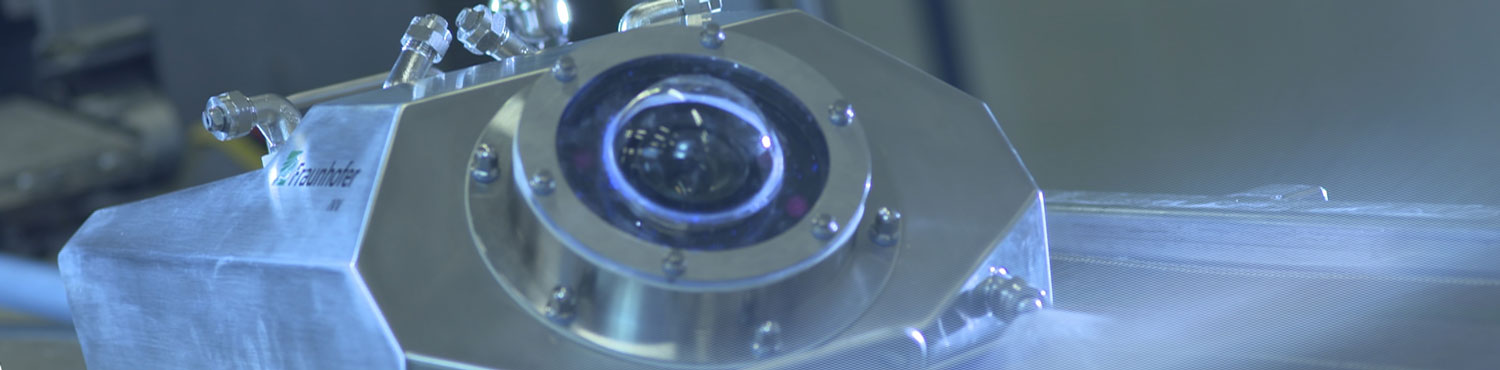

Featuring adaptive target jet cleaning systems rotating around three axes, integrated intelligent contamination sensor technology and digital twin, the Mobile Cleaning Device enables on-demand, resource-efficient cleaning as well as automated documentation and validation of the cleaning process.

Improve the cleanliness of your plant, reduce downtime and increase productivity!

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV