Characterization of web and sheet-like semifinished products has had limitations up until now

All web and sheet-like semifinished products such as polymer films have specific deformation and stretching properties. These properties are decisive for thermoforming, stretch-blow molding, and film stretching processes. Biaxial stretching presents limitations for current measuring systems. The reason is often inadequate clamping of the semifinished product, meaning the real loads acting on the material are not accurately recorded.

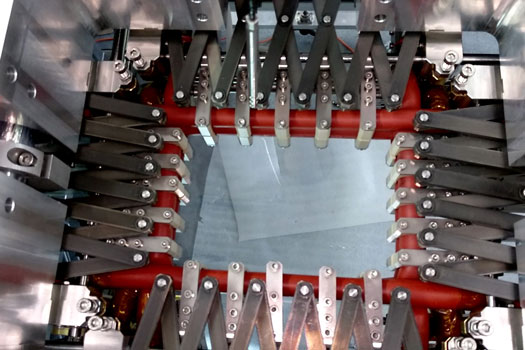

Development of a biaxial tensile testing device with adaptive gripper system

The objective of the research project is to develop a biaxial tensile testing device having an adaptive gripper system for the characterization, modeling, and quality assurance of flat materials at the thermoforming temperature and rate. An elastic element made of heat-resistant silicone allows for the first time secure and uniform gripping of the sample during the whole stretching process. Undesired pinching at the film edges and damage to the material are thus avoided. This means material savings and cost reduction. The measurement of near-real loads on materials during thermoforming processes and the development of a parametrization tool will form the basis for high-quality material models for future simulations. The new tensile testing device will also be evaluated using numerical simulation.

The Fraunhofer IVV Dresden is developing the measuring system for the biaxial tensile testing device and is responsible for experimental validation of the whole system. The project consortium - comprising Fraunhofer IVV Dresden,TU Dresden, and industrial partners - will at the end of the project have a process and system for the accurate characterization of the biaxial stress-strain behavior of flat, thermoplastic polymers under normal processing temperatures (up to 250°C) and forming rates (up to 1000 mm/s).

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV