Protein adhesives developed for greater sustainability

Adhesives need to perform to a high level in the wood processing and furniture production industry

You will hardly find any industry as rooted in tradition as furniture production, where adhesives are used to bond products firmly and permanently. Furniture, windows, doors, stairs, ceiling constructions, etc. are subject to different requirements that depend on their specific field of application.

But even this industry has seen a rise in demand for innovative bio-based adhesives to make it possible to create holistically sustainable furniture using wood, a renewable raw material. Of course, this demand requires the achievement of current adhesive performance with the use of biobased raw materials.

Protein-based adhesives reduce energy requirements for corrugated cardboard production

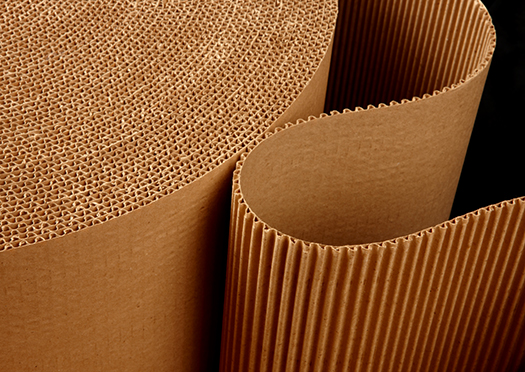

Corrugated cardboard consists of one or more layers of corrugated paper glued to one layer or between several layers of another type of paper or cardboard. Starch adhesives based on corn, potatoes, wheat, and - in some cases - peas are used almost exclusively for bonding corrugated cardboard. These adhesives have a composition of roughly 25% starch and 75% water, which means that the energy consumption involved in drying corrugated cardboard after bonding is extremely high. Synthetic cold glues are an energy-saving alternative to starch adhesives. They can help to achieve a reduction in energy requirements of around 70%. However, synthetic cold glues have failed to become established by the industry, as it would involve replacing a biobased system with a petrochemical-based glue. This system change is a complete non-starter, given the industry’s emphasis on the sustainable origin and character of its products, as well as their recyclability. Thus, the use of proteins can be effective. Increasing the solid content of the adhesive formulation to at least 50% and being able to carry out processing at lower temperatures compared to starch can significantly reduce the energy required to manufacture corrugated board.

Bio-based protein adhesives for wood, furniture, packaging, paper, and corrugated cardboard

The ProWellHo research project serves the described interests by developing sustainable aqueous adhesives and hot melt adhesives for applications in wood processing/furniture production and corrugated cardboard/paper packaging manufacturing. The focus in the areas of wood processing/furniture production and paper/packaging lies on testing bio-based raw materials with the aim of developing market-driven, sustainable aqueous adhesives. The corrugated cardboard production aims to reduce the energy consumption while maintaining a renewable raw material base. To ensure that these project objectives are achieved, the project consortium is covering the entire value chain. Suppliers of various vegetable protein sources as well as experts in the preparation of crude proteins, adhesive development and corrugated cardboard and wood product manufacturing are involved.

A very wide variety of vegetable proteins will be used as the basic bio-based raw material for the planned developments. Based on the experience acquired from the TeFuProt 2 project funded by the German Federal Ministry of Education and Research (BMBF) (Technofunctional Proteins 2, duration: 2018–2021), an increase in water resistance has been proven to be one of the main challenges when using proteins as a raw material for adhesives. In order to address that challenge, proteins will be specifically extracted and modified, and, if necessary, combined with starch components to develop protein preparations with good adhesive strength and high water resistance. This will be done as part of the project being carried out at Fraunhofer Institute for Process Engineering and Packaging IVV.

Project term: |

2023 to 2026 |

Project management / funding: |

Federal Ministry of Food and Agriculture (BMEL) / Fachagentur für nachwachsende Rohstoffe (FNR) |

Project partners: |

|

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV