Practical digitalization solutions for needs-based, secure processes: Fraunhofer IVV at interpack 2023

The Fraunhofer Institute for Process Engineering and Packaging will be pre-senting its new technologies and solutions for business in the packaging and food industry at the interpack trade fair from May 4–10, 2023 at the VDMA booth C54 in hall 4. These new developments can help companies establish digitalized value creation processes and take their first step into the circular economy.

Training up machine operators from any location with virtual reality and digital twins

Fraunhofer IVV is developing digital training systems based on virtual reality (VR) to provide support for vocational training and continued professional development for operating and technical staff. This enables the staff to master the steps involved in processes such as changeovers. The systems will also assist with developing in-depth process understanding as quickly as possible — a necessary step for eliminating and avoiding faults on a long-term basis. The training program can be run as a stand-alone application on VR terminals; there is no need for the machine itself to be present for the training activity. Learners are able to make mistakes and gather experience without impeding a machine’s availability for other uses or even risking damage.

The VR training scenarios are based on a CAD model of the machine and the corresponding process model. This is coupled with a curriculum that is individually tailored to the specific tasks involved in operators’ work and includes a range of learning modules. Visitors to the booth will have the opportunity to try out the training system for themselves using the example of a production plant for thermoformed packaging.

Consultation services for developing future-proof, company-specific digitalization strategies

When it comes to challenges such as ensuring the resilience of processes, implementing the circular economy or addressing skilled worker shortages, digitalization can offer solutions. Fraunhofer IVV assists companies undergoing transformation processes — i.e., implementing concepts such as networked production, the industrial internet of things and data exchanges encompassing the entire value chain — by developing company-specific technology and assistance solutions, individually tailored software for supporting system integration and AI applications for the production process.

Ensuring product safety with intelligent cleaning technologies

The quality of manual processes for cleaning machines, plants and production environments can vary widely. These processes are not reproducible and, in view of the ever worsening shortage of skilled workers, pose major challenges for companies. In view of this, Fraunhofer IVV is working on intelligent technology solutions for automating manual cleaning processes.

At the interpack trade fair, Fraunhofer IVV will demonstrate their AR-based technology CleanAssist, alongside two variants of their Mobile Cleaning Device. These pioneering technological applications enable efficient, resilient production processes that ensure a high level of quality. Cleaning processes can be documented in a fully automated manner using intelligent sensor technology and a digital twin. This means that, it is possible to genuinely validate cleaning processes.

Quality assurance with digital assistance: CleanAssist is the first virtual cleaning assistant for manual cleaning. Tracking sensors on the cleaning lance can be used to analyze and document the rate of volume flow applied (i.e., the rate of cleaning efficiency), as well as spray shadows. A digital twin is transferred to the real-world cleaning environment with the help of an AR device; the actual progress of the cleaning is displayed to the user in real time. This means that areas that have been overlooked, insufficiently cleaned or cleaned too much are visualized to the staff and thus belong to the past.

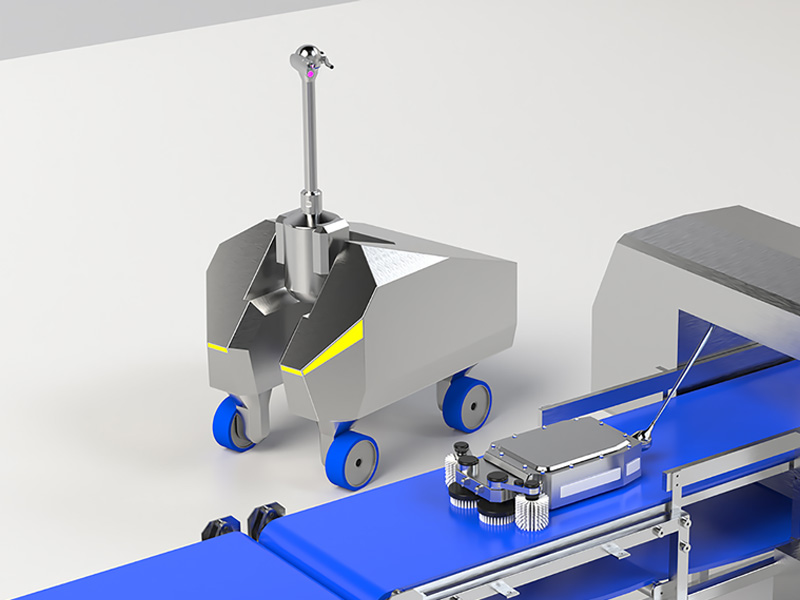

Cleaning 4.0 — fully automated and flexible: The Mobile Cleaning Device (MCD) is an intelligent, modular cleaning robot. Fraunhofer IVV will present two models at interpack for different applications. The first model is an autonomously moving device and can be used for automatic cleaning of entire production environments. The fully integrated contamination sensor technology in the MCD automatically detects the degree of contamination and allows the cleaning process to be documented. An innovative adaptive jet cleaner (AJC), which rotates on three axes, takes care of the cleaning. The second model, an inline version of the Mobile Cleaning Device (Inline MCD), can be used to automatically clean processing plants and process lines. The Inline MCD is additionally equipped with a variety of cleaning nozzles and brushes; during the cleaning process, it travels along the same path as the product through the process equipment, via conveyor belts or rail systems.

First step into the circular economy — natural fiber-based packaging solutions and material substitutes

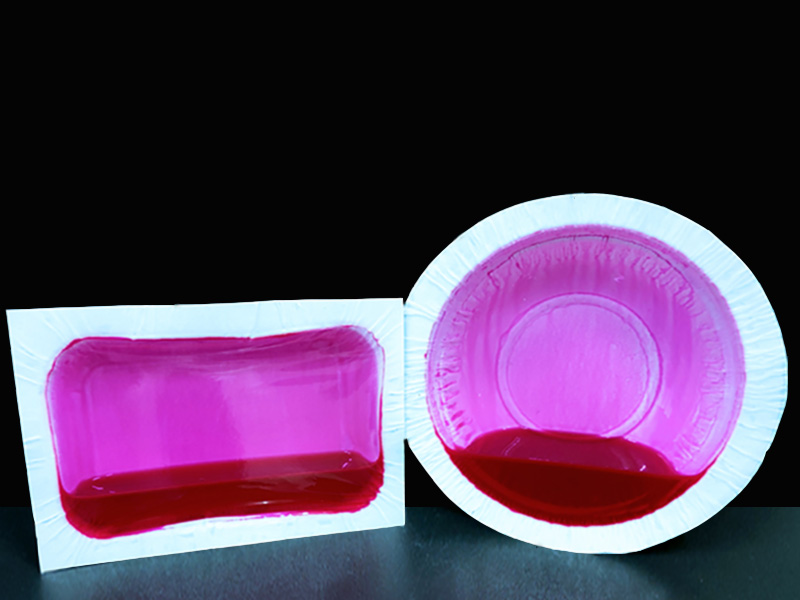

The packaging industry is facing growing demands for recyclable packaging systems — in response, Fraunhofer IVV is developing customized, fiber-based packaging systems and technologies that can reliably control the processing behavior of paper and alternative materials in high-speed machines.

Exhibits will demonstrate the variety of shapes of thermoformed fiber-based packaging that can be created and what can be achieved when 3D molded parts are combined with embossing processes in consumer packaging. They will also show how molded parts can be combined with functional — and sometimes, even organic — barriers.

By focusing on efficiency, safety and feasibility, Fraunhofer IVV offers holistic support for companies making the switch to alternative materials and recyclates. At interpack, the institute will provide insight into advanced forming, joining, measuring and monitoring technologies, as well as research services along the process chain — these range from material selection and characterization to process and machine analysis and packaging design. To this end, Fraunhofer IVV is developing inline monitoring technologies, specifications for process parameterization and needs-based process and machine designs; they are also conducting on-site efficiency analyses in industrial production environments.

Video CleanAssist

Last modified:

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV