Just keep it simple - Patented welding technology for sustainable packaging solutions

New requirements for sealing processes for recyclable packaging

The Packaging and Packaging Waste Regulation (PPWR) stipulates that all packaging must be recyclable by 2030 and that 15 % less packaging material per capita must be used by 2040. These and other legal framework conditions in the packaging industry are leading to the increased use of mono films for packaging in order to improve recyclability. Packaging made from mono-material can be better sorted after the end of life and reused by means of mechanical recycling. However, the processing of mono films is more challenging than with conventional composite films. They have a smaller temperature window during sealing and lead to greater wear on the sealing jaws. Conventional sealing technologies reach their limits in terms of production speed and product quality.

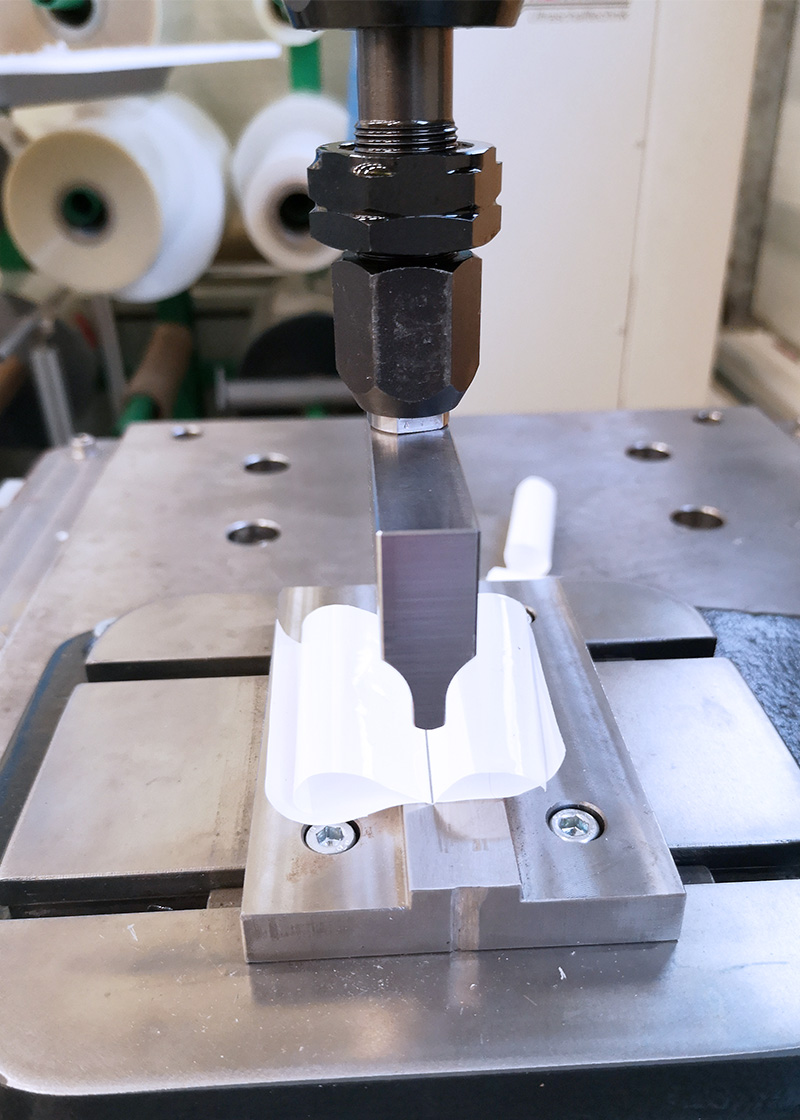

Efficient, safe joining of monomaterials

The innovative and patented high-speed impulse sealing technology (HIS) developed at the Fraunhofer IVV is the answer to these challenges. HIS uses just a single mechanical impulse to generate the required heat precisely in the joining zone. Temperature control of the tools is not required for the process. This makes the technology ideal for recyclable mono-materials and also enables significantly higher efficiency. The process produces very thin, reliable sealing seams with seam strengths of up to 15 N/15 mm and water bath tightness of up to -0.6 bar. The properties of this innovative sealing technology lead to a reduction in material consumption of up to 20 % and a 95 % reduction in energy consumption for sealing.

Wide range of usage options for demanding applications

HIS technology can be used for a wide variety of applications. These range from conventional bag applications to the joining of shrink films and, in future, the joining of trays and cups. The possible product spectrum therefore ranges from technical parts and care products to temperature-sensitive products such as ice cream or chocolate products. The short sealing times of less than 1 ms enable use in high-speed processes, such as confectionery. The cold seal layer can also be dispensed with for cold-sealed products. With its wide range of applications for composite and mono-materials as well as its material and energy efficiency, the innovative technology solution supports the development and production of sustainable packaging solutions. It therefore makes an important contribution to the transition to a sustainable circular economy.

Project information

| Project duration | May 1, 2021 - October 31, 2022 |

| Project Founding: | SAB Validierungsförderung |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV