Industrial cleaning

Your expert partner for hygienic production, cleaning, and sterilization

Today, industrial cleaning is faced with increasing demands for efficiency and precision more than ever before. In view of growing quality requirements and simultaneous cost pressure, we offer you innovative cleaning technologies and processes that are carefully selected regardless of manufacturer and taking into account technical and economic criteria. Our goal is not only to make cleaning easier for you, but also to make it an integral part of your process efficiency and safety.

Due to the increasing shortage of skilled workers, adaptive systems and autonomous robots will help to carry out safe cleaning processes with few personnel. Together, we will find the right solution for your company size. Our specialized sensor technology detects contamination in real time and enables demand-oriented process control.

We use simulations to optimize your cleaning processes in advance, without the need for costly testing in the production environment. Assistance systems later support your staff's understanding of the process. We train your staff directly in the process and use machine learning to permanently eliminate or completely prevent malfunctions.

Our solutions are customized and documented step by step to meet your requirements in order to maximize safety and efficiency. Our cleanability tests and customized hygienic design solutions make a decisive contribution to compliance with hygiene standards, whereby we always work in accordance with the latest EHEDG and GFSI guidelines.

In addition, we contribute to the effectiveness of your disinfection and sterilization processes with microbiological validations, thus ensuring quality and safety along your value chain. With intelligent tank cleaning solutions that automatically adapt to process conditions, we avoid oversizing and increase process efficiency.

In addition to cleaning in the production environment, we are proven experts in the field of component cleaning. We don't just see this as a cleaning process, but as a value-adding step for which we develop comprehensive solutions for design, monitoring, and digitalization.

With our approaches, you can be sure of optimal cleaning processes with the highest quality, efficiency, and sustainability!

Take part in our events!

We present trends and the latest technologies for use in production at trade fairs and regular events.

Innovative cleaning systems for industrial applications

Would you like to automate cleaning processes and use the latest, most efficient systems?

Benefit from our long-standing, manufacturer-independent expertise in both common and innovative cleaning, sensor, and automation technologies. We enable you to run your cleaning processes reliably and reproducibly, while achieving near-optimal efficiency.

Our cleaning systems are continuously being developed to meet even the most demanding requirements in the future. Special multi-sensor systems can already support humans and machines with the data required for safe process control to an unprecedented extent, and we are continuing to research these systems.

We work with you to develop customized automation solutions!

Adaptive cleaning systems and robotics

Would you like to say goodbye to your worst-case scenario-based and therefore oversized cleaning process? Would you like to waste fewer resources and reduce cleaning time?

With our work on adaptive cleaning systems, we support the paradigm shift from experience-based to model-based design, parameterization, and control!

Using multi-sensor technology, we implement systems that detect the necessary cleaning effort based on the type, condition, and quantity of contamination or product residues. Flexible cleaning systems with a high degree of freedom (e.g., robots) use this information to clean with pinpoint accuracy.

How about having your machinery, equipment, or even your entire production environment cleaned by intelligent cleaning robots in a reproducible, demonstrably safe, yet flexibly tailored manner according to your needs? Take advantage of our Mobile Cleaning Devices (MCD) and our customized solutions for robot-assisted internal cleaning of your systems, or for cleaning production rooms (e.g., cooling chambers, cooking rooms), or for the entire production environment. In addition, a wide range of powerful systems for adaptive, need-based tank cleaning are already available.

If the systems currently available do not meet your requirements, we will work with you to develop a customized solution.

We accelerate the digitalization of your cleaning!

Cleanability tests & hygienic design

The cleanability of your products can be validated, visualized, and quantified!

We have a unique method using fluorescence-based inline contamination detection, which visualizes and evaluates cleanability. In addition to a before-and-after check, time- and location-resolved monitoring of the entire cleaning process is possible, allowing a spatially-resolved, differentiated view of cleanability.

This allows the cleaning time required for each point of single components or component groups to be determined. An individual test setup helps to convey the advantages of hygienic design components in a measurable and visual way and can also support the design development process.

We also come directly to your production facilities with our mobile contamination sensors and carry out an analysis of the cleaning processes on site. During the CIP cleaning of your tanks, for example, we precisely track contamination by location and over time, leveraging these insights to enhance cleaning efficiency and reduce resource consumption.

With our comprehensive know-how and equipment, we support you in designing your machines and processes for easy cleaning.

References:

The EHEDG cleanability test for open systems

The test allows equipment and component manufacturers to evaluate their machine and plant designs based on EHEDG standards early in the development process.

Cleaning simulation

Short, efficient cleaning processes while ensuring consumer safety and product functionality are ideal from both an economic and ecological point of view. A purely experience-based design is not effective, as iterative, experimental testing is time-consuming and expensive.

To optimize industrial cleaning processes, we therefore use a variety of simulation methods tailored to the specific application and target parameters. Detailed information obtained through computational fluid dynamics (CFD) contributes to cost reduction and acceleration of development processes, as do spray shadow analysis using semi-empirical models and dimension-reduced simulation of fluid distribution.

Experience has shown that all cleaning processes – both open spray cleaning as well as closed cleaning in pipes and tanks – can be designed much more efficiently using simulation. We support you in unlocking this potential.

With our wide range of simulation methods, we optimize your cleaning processes – in a resource-saving and modern way.

Assistance systems for industrial cleaning

Industrial cleaning processes are primarily designed based on the experience of the operators. Similarly, adjustments and the elimination of problems and malfunctions are carried out based on the knowledge of operating personnel. However, the departure of experienced employees often results in a loss of know-how, which new employees can only regain and apply after a long training period. Quality problems, unnecessary use of resources, and high costs are a frequent consequence.

We develop customized digital solutions to address these challenges, including self-learning operator assistance systems. These systems enable even inexperienced personnel to quickly learn how to effectively support the elimination of faults by offering direct recommendations for action. The software combines machine learning based on historical and sensor-based system parameters with human experience, enabling the effective and efficient operation of systems and the quick rectification of faults.

Personnel are trained during the ongoing process and faults are eliminated in the long term through machine learning.

Sensors for contamination detection

Contamination poses a risk to subsequent processes, the functional reliability of components, and even consumer safety. The safe removal and monitoring of any residual contamination is therefore essential, which is why we develop tailor-made, specific solutions for our customers.

Fluorescence measurement technology for filmic contaminations

Most filmic contaminations emit light in the visible range when excited by ultraviolet radiation. We use this effect, known as "fluorescence", for contamination detection by means of image-based cleanliness control. The sensor technology provides spatially- and time-resolved information about the type, condition, and quantity of contamination.

Our fluorescence measurement methods are suitable for:

- Troubleshooting

- Process optimization

- Quality control

- Documentation

We develop application-specific system and sensor solutions for your processes for inline measurement of the quantity and type of filmic contamination.

CoControl

CoControl-LumiHD

This sensor is the first extremely compact hybrid system for large-area contamination detection that evaluates information under both UV and white light excitation. The sensor is developed in hygienic design and can therefore be used directly in hygienically sensitive areas. The combination of fluorescence properties with the typical optical characteristics of residues enables even more reliable detection of the type and condition of contamination. This means that non-fluorescent residues can also be detected for the first time.

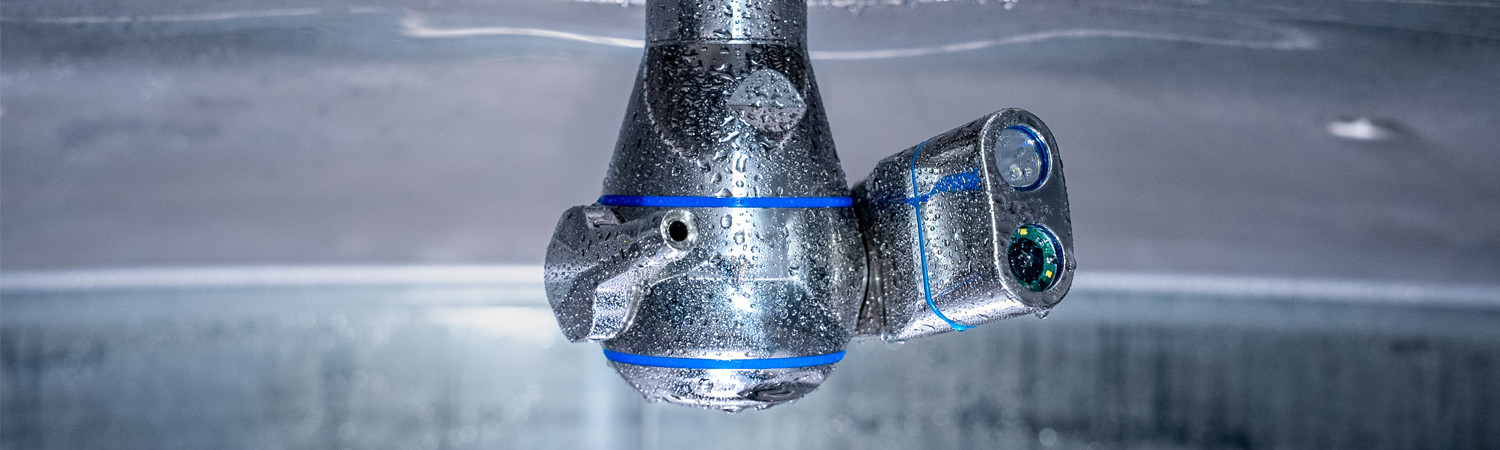

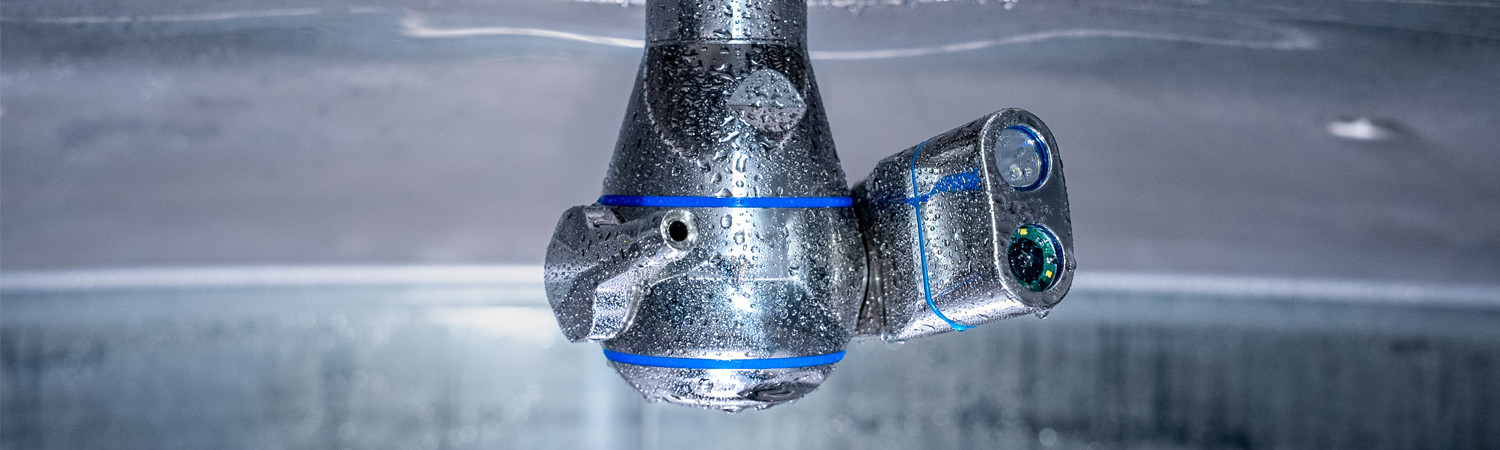

CoControl-Lumi3D

Available as an inline application or as a separate measuring box, this module enables complete, fast, and reproducible contamination detection on complex 3D components for the first time.

Unlike our conventional systems, which detect film-like contamination in one or two dimensions, CoControl-Lumi3D is able to assign the contamination detected without contact and over a large area to a specific position in space. If the 3D model of the component is linked to the information obtained, functional areas such as seals or joints can be selectively checked for compliance with the required cleanliness criteria.

Do you have inaccessible areas where visual inspection for residual contamination is not possible? We have developed a compact sensor solution that uses vibrations to monitor minimal residues of contamination in closed systems such as pipelines. This not only enables cleaning to be carried out as required, but also allows the cleanliness status to be continuously monitored in areas with full flow.

CoControl-FouliQ

Using artificial intelligence (AI), the occurrence of fouling in heat exchangers during production can be predicted in real time for the first time. An AI model predicts the required temperature at the heat exchanger inlet for stable heating of the product to a constant temperature.

In addition, the energy requirement increases due to the reduced heat transfer and therefore the costs for heating increase considerably. »CoControl-FouliQ« enables the energy required for heating to be evaluated and provides a basis for decisions regarding cleaning cycles.

We develop contamination sensors that keep you on the safe side when it comes to process technology!

Tank cleaning tailored to your needs

Want to say goodbye to your oversized tank cleaning processes designed for worst-case scenarios because they waste unnecessary resources? With our adaptive cleaning systems, we support the paradigm shift from experience-based to model-based design, parameterization, and control.

We work with you to analyze your cleaning processes and identify critical areas in the tank. By combining innovative sensors and tank cleaning systems, we ensure that every cleaning process is always tailored to your needs thanks to intelligent monitoring and control.

To this end, we developed the revolutionary AJC (Adaptive Jet Cleaner), the first tank cleaner that allows cleaning paths to be individually adapted to the tank geometry. This allows areas that are difficult to clean to be cleaned more intensively than less critical areas.

The further developed AJCsens also has an optical contamination sensor integrated into the device. This continuously analyzes the current contamination status and forwards the information to the intelligent control system of the AJCsens. The cleaning process is adjusted inline as required and the cleanliness status is documented at the end.

By using steam for CIP cleaning of tanks, we have achieved additional resource savings, which can lead to further reductions in your cleaning costs.

We can implement fully automatic cleaning for you: resource-saving and cost-effective!

Industrial component cleaning

Industrial component cleaning is a quality-enhancing and therefore value-adding process. Based on this conviction, we have been developing comprehensive solutions for the design, quality assurance, and digitization of cleaning processes since 2008. To achieve this, we identify and leverage optimization potential in the complex interaction of chemistry, process engineering, equipment and measurement technology, as well as in upstream and downstream processes, logistics, and staff training.

The core elements of our service portfolio include the controlled generation, aqueous removal, and fluorescence-based measurement of filmic and particulate contamination as part of cleaning and process chain analyses.

In our application center, you can experience future technologies for process data acquisition, operator assistance, and functional surface cleaning live and test them for your cleaning task.

The complexity of industrial component cleaning offers opportunities. With our services, you can turn these into advantages for your company!

Determination of cleanliness according to VDA 19.1/ISO 16232

Alongside film-like contaminants, particulate residues pose the greatest challenges in the manufacture of components. Would you like to optimize your cleaning processes and test new methods for removing particulate contaminants? We offer comprehensive support options for this, such as determining cleanliness requirements and ensuring compliance with VDA 19.1 / ISO 16232. We can also take film-like contamination into account, providing you with a comprehensive picture of the quality achieved.

To ensure the high standards at Fraunhofer IVV, we have established a quality management system in accordance with the requirements of DIN EN ISO/IEC 17025 and thus in accordance with ISO 9001 for testing laboratories.

For example, to reduce packaging material and petroleum-based packaging and fillers, alternative packaging materials such as cardboard/paper are increasingly being used. When cleaned components come into contact with these fiber-based materials, abrasion can occur, resulting in additional particles and fibers on the components.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV