Active packaging for a longer shelf life

Each week, food retailers end up ditching as much as 50 percent of their stock of fruit and vegetables. It’s a similar story with consumers. There are two main reasons for this wastage: premature ripening, which in many fruits is triggered by ethylene, a plant hormone; and microbial infestation, often in the form of mold. Yet the use of active packaging can help slow these processes and prolong the shelf life of fresh fruit and vegetables, thereby reducing food waste. The recently completed CorNet project »FreshInPac« addressed both of these aspects.

Modified atmosphere packaging and active substances

To combat microbial spoilage, a series of natural substances, essential oils and extracts were tested on a representative selection of mold, yeast fungi and bacteria. The most promising substances demonstrated an inhibiting effect against all test organisms. Minor weaknesses in individual substances can be offset by combining them with others. The selected substances were sufficiently heat-resistant to withstand extrusion processes. Some substances continue to be active even when applied in the form of a paper coating or following extrusion in films. Although the effect is partially reduced, storage tests have shown that the antimicrobial substances effectively inhibit microbial spoilage.

Ethylene deploys its ripening-promoting effect when it exceeds a certain concentration. As it is a gaseous substance, it builds up after it is released within the packaging. Active packaging components that effectively remove ethylene from the packaging’s atmosphere therefore help to slow down ripening. There are a range of suitable materials, such as various minerals that can be used by themselves or those that can be deployed as a carrier for potassium permanganate, that are inherently particularly well suited to reducing the ethylene concentration to an acceptable level. Unfortunately, the process of introducing these substances into the matrix of the packaging or packaging coating causes the active constituents to be almost completely blocked, meaning that they are no longer effective. However, they could continue to be used in the form of sachets.

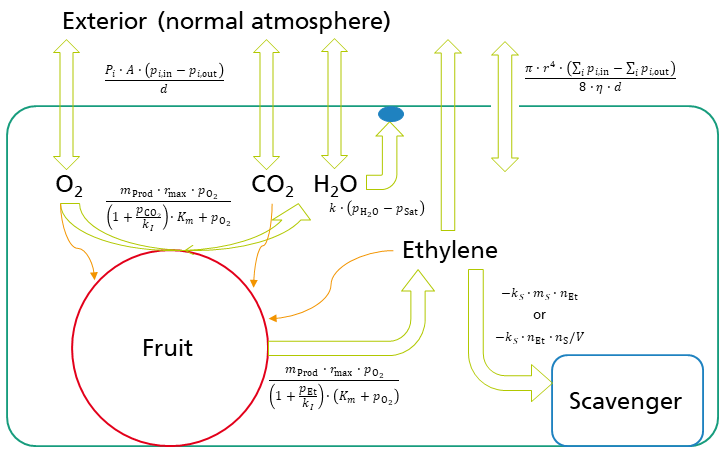

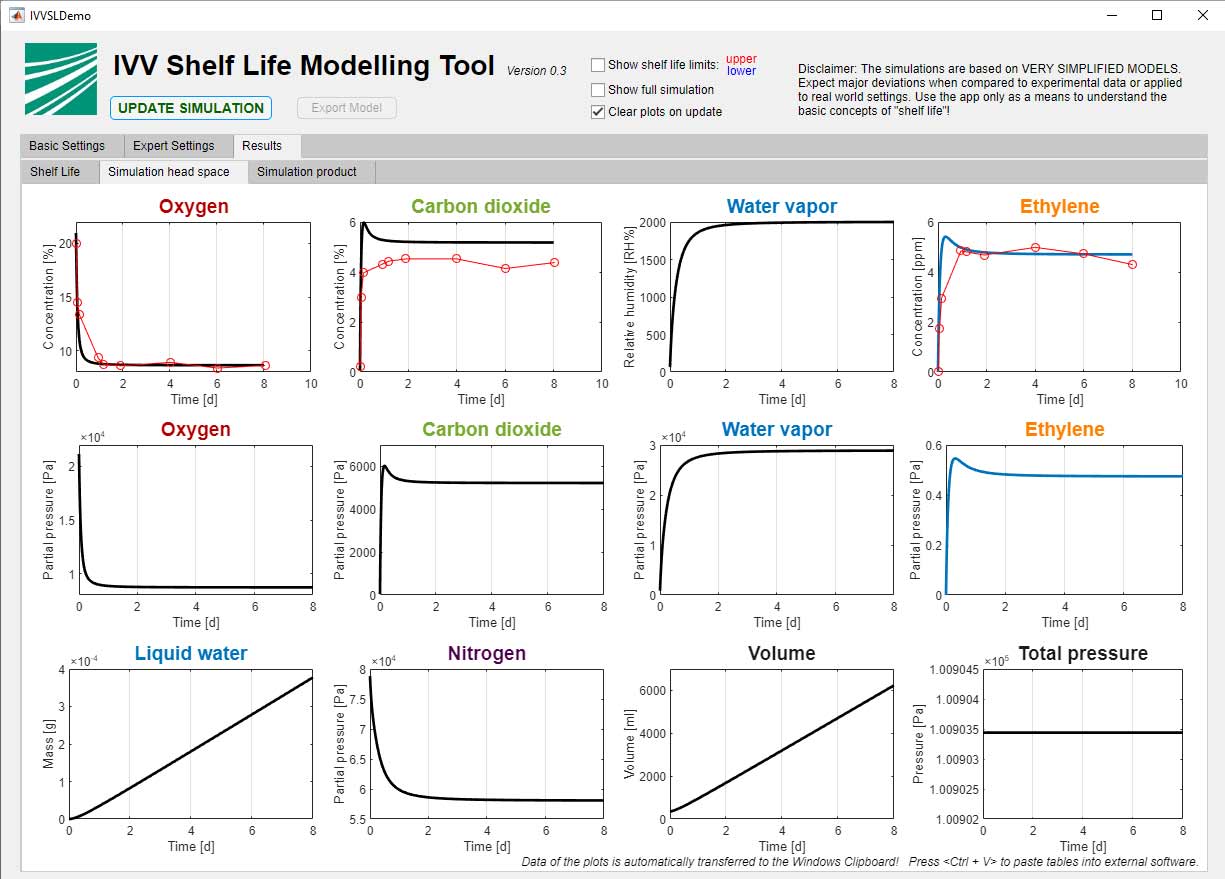

Simulations for development of new packaging

At Fraunhofer IVV, mathematical models that describe the respiratory behavior and ethylene content have been implemented and corresponding simulations have been carried out to facilitate the targeted design of active packaging. When packaging fruit and vegetables, materials should be selected that allow the contents to breathe and that prevent fermentation under anoxic conditions. Packaging with an overly strong gas barrier is therefore unsuitable for this purpose. This knowledge is used by the EMAP (equilibrium modified atmosphere packaging) concept, which strikes a balance between respiration and gas exchange by incorporating small perforations in the packaging. This creates an atmosphere inside the packaging that has lowered oxygen levels and elevated carbon dioxide content. The reduced oxygen content slows down respiration and the production of ethylene in the product, while the higher concentration of carbon dioxide also inhibits respiration as well as suppressing the growth of microorganisms. As our shelf-life simulations have shown, effective EMAP would result in too much ethylene building up inside the packaging. The addition of an ethylene scavenger can then complement the EMAP and create conditions to prolong shelf life.

Project term: |

2019 bis 2022 |

Project management |

German Federation of Industrial Research Associations (via the Industry Association for Food Technology and Packaging), German Federal Ministry for Economic Affairs and Climate Action |

Project partners: |

|

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV