New test method for the realistic evaluation of the machinability of flexible packaging materials

Optimum machinability of flexible packaging materials is crucial for efficient and safe processing. The realistic assessment of the dynamic coefficient of friction is particularly important when switching to recyclable packaging materials. This depends, among other things, on the relative speed of the packaging material against the tool surface. According to current standards, existing test methods are only carried out at low speeds and are therefore at odds with the real conditions in processing and packaging machines. In practice, these are often operated at very high speeds or cycle rates.

In order to counteract this discrepancy, we have developed a new, realistic test method for determining the real coefficient of friction as part of the WIPANO research project and converted it into a standard (VDMA standard sheet).

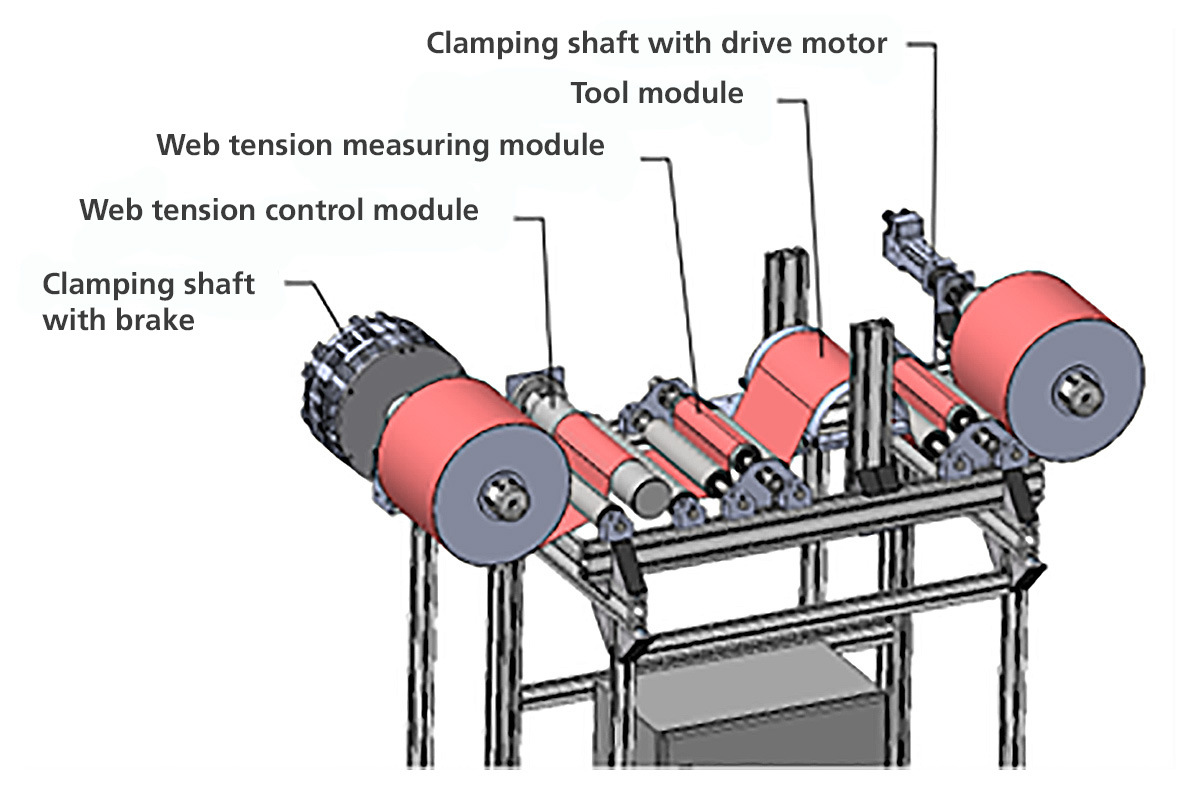

In our test method, the packaging material is pulled over a tool. This allows the real load conditions of an industrial machine to be reproduced on a laboratory scale. In addition, endurance tests, for example to examine the service life of a coating and investigations into the influence of the tool material and surface, as well as the wrap angle, are now also possible.

Last modified:

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV