Digitization solutions and AI for processing

Digitization solutions and AI for processing

The shortage of skilled workers, competitive pressure from private labels, and the need to respond quickly to trends and regulatory requirements pose challenges for manufacturers of food, pharmaceuticals, and cosmetics. We see digitalization as a tool for solving these problems.

To this end, we combine our expertise in software development, data science, mechanical engineering, automation technology, didactics, and engineering psychology to develop applied digitalization solutions. Our digital assistance systems compensate for differences in the qualifications and experience of machine operators. We shorten the onboarding process for new staff by using virtual training courses in which they learn about processes and how to do their jobs without having to take your machines out of production. We secure the knowledge available in your company by applying psychological methods and make it accessible to your employees within the company via chatbots.

Our digital simulations allow packaging materials to be tested under real conditions and recommendations to be obtained for packaging selection and process and material optimization. For the design of machines and systems with regard to optimum cleanability, we have developed innovative software for spray cleaning simulation that maps the cleaning process and determines the expected cleaning effect on complex surface geometries.

Digitalization is much more than technical progress—it is a strategic key to future viability!

Digital assistance systems

Do your operating personnel lack the experience and expertise to operate your machines and systems efficiently and without errors? Does the training or onboarding of new personnel take too long? Do your staff react inadequately when malfunctions and machine downtimes occur?

We develop customized digital assistance systems to help you overcome the shortage of skilled workers. These act as digital knowledge repositories in which machine- and production-specific knowledge, experience, and instructions for performing work tasks are stored. The knowledge base is filled and kept up to date by applying our knowledge retention methods, which involve training your staff or implementing the formats with your personnel.

Your operating or technical personnel can easily access the knowledge via task-oriented user interfaces on a smartphone, tablet, or PC. If you want your operators to be supported in troubleshooting and fault elimination, a specially trained AI model analyzes machine and sensor data from your plant. Using the patterns recognized in the model, the entries from the knowledge database that are appropriate for the situation are called up. With the help of the work instructions presented, even untrained and inexperienced employees can quickly and accurately troubleshoot problems and keep downtime to a minimum.

Our assistance systems allow you to deploy your personnel flexibly in production. This means that personnel bottlenecks can be better compensated for while maintaining the same level of production efficiency.

We develop operator assistance systems that are tailored to your processes!

Qualification of personnel

Do you want to provide your operating personnel with contextual knowledge and practical skills for your machines and systems? Due to the shortage of skilled workers, do you increasingly need to train new personnel quickly and efficiently? The machines required for training purposes can’t be taken out of production?

With our VR-based training courses, you can train your operating and technical personnel flexibly in a virtual environment away from production. A customized didactic concept enables the rapid and clear communication of skills and makes even complex process relationships interactive, tangible, and easy to learn. Your employees learn how your machines work, as well as the interdependencies and constraints of the processes that take place within them, away from production. The easy-to-understand visualizations of complex issues enable a high level of understanding to be achieved, regardless of the native language of the personnel.

By combining process knowledge and practical skills, you enable your staff to deal confidently and efficiently with malfunctions, machine downtime, and quality deviations. The quick and error-free execution of format changes, which can significantly reduce setup times, can also be taught. In addition, VR training courses optimally prepare your personnel for the manufacture of seasonal items by reminding them of special features of machine settings and the processing characteristics of products, semi-finished goods, and packaging materials.

Virtual reality training ensures efficient onboarding of new operating personnel. At the same time, it enables you to raise the skill level of your existing workforce, reducing operating errors due to insufficient training. This minimizes disruptions, shortens workflows, and increases production efficiency.

We will work with you to develop your individual training concept!

Securing knowledge within the company

Is most of your company's specialist knowledge concentrated in the hands of a handful of experienced employees? Are you concerned that this important knowledge will be lost when employees leave? Do you want to lay the foundation for securing and passing on knowledge within your company in the long term?

Company-specific expertise gives you an important competitive advantage over your competitors. However, this expertise is usually tied to individuals, which means that if they leave the company, you risk losing this critical competitive advantage. To prevent this, you need systematic and customized knowledge management.

We support you in creating a knowledge retention plan tailored specifically to your company and in implementing it with your employees. Depending on whether there is a concrete risk of knowledge loss or whether you want to develop a long-term solution for everyday work, we can support you in finding the perfect solution for securing your company-specific knowledge using various methods of engineering psychology. If, for example, a specialist in troubleshooting and repairing your production machines is approaching retirement, their experience can be captured in a series of interviews using the Critical Decision Method and Forward Scenario Simulation and then prepared as content for your existing knowledge management system or used as a basis for training new personnel.

Use cases for manufacturers (e.g., food, pharmaceuticals):

- Machine operators

- Technicians

- Maintenance personnel

Use cases for machine manufacturers

- Technical service

- Commissioning

- Design and development

Secure what makes your company what it is: the knowledge and experience of your employees!

Quality assurance & product monitoring

»imageSAM«

Do you have one or more production employees standing next to your processing line performing visual quality checks? Are you finding it increasingly difficult to find staff with sufficient experience and expertise in times of skilled labor shortages? Is your production frequently at a standstill due to quality defects?

Our technologies ensure consistent quality assurance for your production processes.

For this crucial process, we have developed the "imageSAM" assistance system, which enables you to continuously and automatically monitor the quality characteristics of your products and semi-finished goods at critical points in production. To do this, we equip your plant with cameras and analyze the images captured using an AI model developed specifically by us. "imageSAM" identifies deviations from your specified quality criteria and recognizes the type of error. Put simply, "imageSAM" automatically detects all deviations and errors that your staff can identify and distinguish through manual checks.

Your staff is informed of the occurrence of errors via tablet or smartphone. Instructions support operators in implementing precise measures to eliminate errors. This means that even inexperienced staff can make the correct settings on the machine safely, quickly, and without errors, eliminating human misjudgments. In addition, "imageSAM" automates the documentation of production monitoring.

Quality monitoring on the production line – we automate manual visual quality checks!

HMI-Consulting

Do you want your machines and systems to be operable even by operators with low skill levels? Do you want machine data to be interpretable and usefully visualized for all operators? Do you want to benefit from proven psychological insights when developing HMIs for your processing and packaging machines?

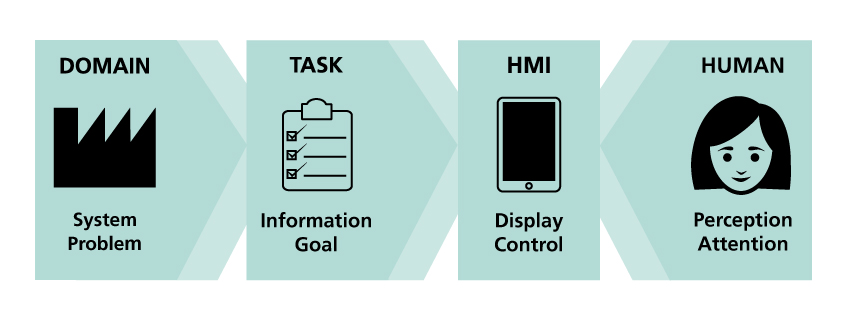

By combining interdisciplinary expertise in engineering psychology, mechanical engineering, and automation technology, we bridge the gap between data and design. By analyzing the various operating tasks specifically for your machine, we are able to adapt the amount, composition, and level of detail of information in the HMI to the information needs of the personnel. Insights from psychology are used to adapt the presentation of information to human perception, cognition, and action.

Improved availability and consistency of the information displayed make machine functions and the effects of the settings made more transparent and easier to understand for personnel. This leads to reduced training requirements, faster onboarding, and machine operation with fewer errors.

- Explore our HMI consulting services

- Assistance system for the cooperative development of human-machine interfaces – KoHMIdes

We would be happy to advise you on optimizing your user interfaces. Get in touch!

Process simulation

Are your development processes too time-consuming and costly? Do you lack the in-depth process understanding needed to derive effective optimization approaches?

Then take advantage of our simulation expertise! We increase the stability and efficiency of your processes while expanding your understanding of them. This allows you to reduce or even completely eliminate expensive and time-consuming test cycles.

Whether cleaning processes, material or process modeling – our simulation models are individually tailored to your specific requirements. For example, we can realistically simulate the behavior of contaminants in the cleaning process, optimize processes, and design customized products.

Based on a detailed process analysis, we model the relevant components of your system. Using various commercial and open-source simulation programs, we can investigate thermal, structural, and fluid dynamic relationships and their interactions. Our expertise covers element selection and networking, model selection and contact definition, and the specification of boundary conditions and loads.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV