Innovative packaging solutions to extend the freshness of bakery products

More than 20% (equivalent to about 800,000 metric tons) of the bakery products sold each year in Germany end up being thrown away. This is due to various chemical and biological processes adversely affecting product quality. For example, fresh bread in conventional packaging loses some of its flavor and crustiness after just 24 hours.

Reducing food wastage: Development of packaging with moisture regulation

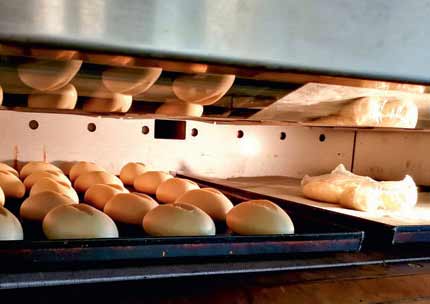

The Fraunhofer Institute for Process Engineering and Packaging IVV and Technologie-Transfer-Zentrum (ttz) Bremerhaven are working together on an IGF project entitled 'BackPack' to develop a transparent, oven-proof, moisture-regulating packaging which allows product to be baked in the packaging and has a number of other benefits:

- The moisture-regulation functionality of the packaging reduces condensation build up during baking and drying out during storage. As such, the freshness of the bakery products is prolonged and food wastage reduced.

- Baking temperatures of 200°C kill vegetative germs and spores. If products are kept in their packaging after baking, then contamination with germs from the surroundings is not possible.

- Baking inside a packaging enables products for both allergy sufferers (e.g. gluten intolerance) and non allergy suffers to be baked together. This is particularly relevant for small bakeries.

Combination of experimental methods and mathematic models

Baking trials at ttz Bremerhaven determined the water release during the baking of various products. These findings have been used in conjunction with mathematical models developed at the Fraunhofer IVV to calculate the ideal water vapor permeability of the packaging film for baking (T=200°C) and storage (T=23°C).

During the baking process, large amounts of water vapor are released and this has to be efficiently removed from the packaging. In contrast, during storage at room temperature it is desirable for the packaging to have a low permeation rate in order to prevent drying out of the bakery products. The challenge is thus to develop a packaging material having adaptive moisture management. Simulations have shown that even highly permeable materials such as cellulose have insufficient water permeability to prevent condensation build up during baking.

Development of packaging material having adaptive moisture management

A potential solution is to use a highly perforated packaging film in combination with a swellable lacquer. The lacquer swells at high temperatures and high humidity, enabling water to be removed through the pores. After baking, the lacquer contracts again and the pores close. To verify this, a variety of polymer coatings and lacquers are being manufactured at the Fraunhofer IVV and baking tests are being undertaken at ttz Bremerhaven. In parallel, the packaging materials will undergo migration tests to ensure they comply with food legislation.

Project term |

2019 to 2021 |

Project management |

Federation of Industrial Research Associations AiF (via the Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. (IVLV))/Federal Ministry for Economic Affairs and Energy (BMWi) |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV