Open innovation ecosystem for sustainable nano-functionalized plastic and paper surfaces and membranes

RESEARCH PROJECT "FlexFunction2Sustain"

Europe-wide network enables innovative developments in plastic and paper packaging

Lack of development resources for SMEs and start-ups

There is a growing need for the development of innovative, sustainable plastic and paper packaging materials. Due to demand and political regulations there is a shift towards new packaging concepts that are more resource-friendly and recyclable. Especially small and medium-sized enterprises and start-ups are keen to see the market integration of innovative ideas involving new and high functional materials as well as new packaging designs. However, they do not have the resources required to put their ideas into practice and develop them to the point of market readiness. In particular, the lack of infrastructure in the areas of material development, testing and pilot production capacities should be mentioned here.

A network for innovative functionalized technologies

Now, the EU’s FlexFunction2Sustain research project has brought together 19 European partners from research and industry to pool their expertise, practical and scientific skills as well as technical infrastructure, creating a sustainable, open network for innovations. In the Open Innovation Test Bed (OITB), the project partners hope to give companies the ability to trial nano-functionalized technologies which will facilitate sustainable, intelligent packaging, surfaces and membranes based on plastic or paper.

During the first stage of the project, the consortium worked together on various case studies:

- Procter & Gamble: marine-degradable shampoo sachets

- SONAE MC: paper-based fresh food packaging

- HUECK Folien: biodegradable security labels

- Capri-Sun: recyclable drink pouches

- Centro Ricerche FIAT: innovative polymer surfaces in car interiors

- i3 Membrane: selective and switchable water filter membranes

This enabled all participating institutions to compare their expertise and resources and thus decide to what extent industry partners should be helped to realize their ideas. In-house facilities were also upgraded to the latest technology. In the second phase of the project, companies that were not part of the consortium and would like to test their innovative packaging concept were sought through calls for tenders. The following applications are of interest for the project:

- Sustainable, intelligent packaging

- Surfaces and membranes in filtration, medical and bio applications

- Plastic and paper electronics

- Optical films for security and design

- Smart plastic films for architecture applications

- Smart plastics in automotive application

Pilot studies FlexFunction2Sustain

FunFlex

Aim of the pilot study: Development and implementation of novel recyclable monomultilayer structures based on advanced BarriLack coatings.

Our contribution:

- Concept Design4Recycling

- Barrier enhancement

- Foodstuff conformity

Possible areas of application:

- Tray cover

- Snack packaging

- High functional pouch packaging

RECYBIB

Aim of the pilot study: Development of a mono-material polyethylene (PE) bag-in-box with oxygen barrier properties, without the use of EVOH.

Our contribution:

- Development of barrier technology using BarriLack

- Concept Design4Recycling

- Shelf life simulation

Possible area of application

- Drink pouch

POSEIDON

Aim of the pilot study: Further enhancement of the Sylvicta paper with an additional water vapor barrier layer for packaging liquid goods while maintaining recyclability.

Our contribution:

- Development of new barriers

Possible areas of application

- Drink pouch

- Sauce sachets

Sustainpack

Aim of the pilot study: The aim of this project is to develop fully recyclable biodegradable and/or bio-based packaging concepts with different barriers.

Our contribution:

- Application of PVOH on different base materials

- Co-Extrusion of PVOH and bio-polymers

- Recyclability test

Possible area of application

- Foodstuff packaging

Expertise in developing sustainable packaging materials

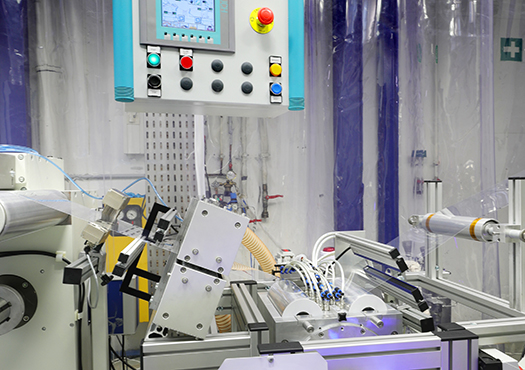

Through their many years of experience in developing packaging, the experts at Fraunhofer IVV are able to help companies create biodegradable and recyclable packaging with exceptional barrier properties. Their work includes developing, characterizing and analyzing various barrier concepts such as coating, metallization and SiOx vapor deposition. The institute is also able to create coatings and film finishes on a pilot scale using a variety of coating techniques, such as reverse gravure and slot-die coating. Not only that, but coatings tailored to the needs of the application in question can also be developed on flexible substrates using the roll-to-roll ALD method. An advanced coating unit is being installed for this purpose as part of the project. Additionally, the institute’s dedicated packaging facility offers the option of extruding polyolefin films from recyclates and then characterizing them on the basis of the RecyClass protocol. Once a prototype film has been designed and manufactured, there are numerous analysis methods available to choose from, including:

- Determining the thermal properties and melting parameters using DSC and MFI measurements

- Analyzing the surface tension and energy of the coating and substrate

- Measuring barrier properties in the face of various gases at various temperatures

- Determining the mechanical properties of packaging materials, such as tensile strength, elongation at break, adhesion and puncture resistance

- Visually analyzing surfaces and cross-sections using microscopy, REM and AFM

- Plus many more

Project term: |

1.4.2020 to 1.4.2024 |

Project management |

EU, European Union’s Horizon 2020 research and innovation programme |

Project partners: |

|

Website: |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV