As current crises demonstrate, even industrialized countries are inadequately protected against food supply shortages. Researchers from the Fraunhofer Institute for Process Engineering and Packaging IVV are working on tools to make the food sector more crisis-proof.

From the empty supermarket shelves during the coronavirus pandemic to food shortages and rising prices in the wake of Russia’s attack on Ukraine — not to mention the ongoing threat of famine around the world due to climate change, heatwaves and flooding — current crises have exposed the weak points in our food supply. They have come at a time when the food situation is already under strain across the world on account of the rising global population and climate change. Droughts, heavy rain and other extreme weather events resulting from global warming are causing crop failures worldwide, including in Europe.

Guaranteeing a supply of high-quality, wholesome food is crucial. But how can the food industry become more resilient, i.e. more resistant to crises? "Resilient value chains for food production" (German only), a white paper by the Fraunhofer institutes IPT, IME and IVV, analyzes resilience factors and provides recommendations for action. On top of that, Fraunhofer researchers have developed a Resilience Evaluator (FReE) (German only) that companies can use to put their resilience to the test. Together with Fraunhofer EMI and the AFC Consulting Group, Fraunhofer IVV has specifically adapted the evaluator to the food industry. The food industry is distinct from other sectors because its products are susceptible to spoilage and contamination by microbes. As a result, the requirements for food safety are high. For example, entire goods flows could be rendered inedible if spoilage agents or pathogenic germs — which are almost impossible to detect in the raw material — multiply across the value chain. This, along with natural ripening and spoilage processes, mean that quick and smooth logistics are more crucial to product quality in the food industry than in many other sectors of the economy.

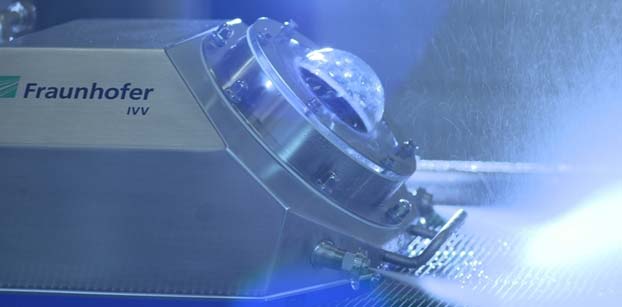

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV