Intelligent sensor monitoring for reproducible manual cleaning

Manual cleaning processes are naturally subject to significant fluctuations in quality and are therefore critical for process reliability. In order to be able to guarantee a safe and reproducible cleaning process for the first time even in manual spray cleaning processes, a sensor-monitored cleaning lance was developed in the "CleanAssist" project.

Innovative sensor technology integrated within the lance enables cleaning to be logged. The cleaning performance is recorded automatically by documenting all relevant process parameters and the cleaned areas.

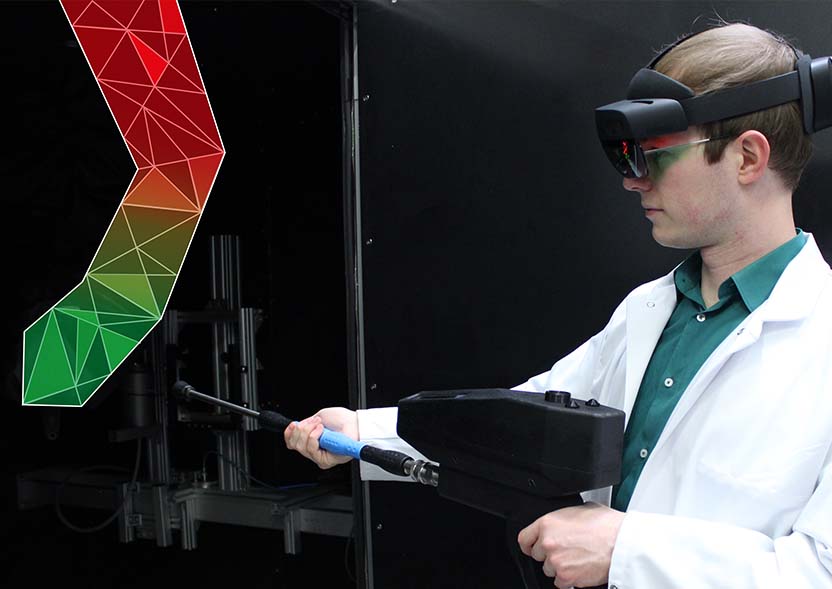

Digital twin and augmented reality (AR)

By subsequently transmitting the process parameters and position data of the spray lance to a visualisation device (for example AR data glasses), a digital twin of the cleaning process is projected into the real production environment. The operator of the cleaning lance is shown his own cleaning performance as well as the areas that still need to be cleaned.

Clean Assist provides support for targeted cleaning and in selecting the appropriate cleaning process. It also ensures that the volume flows, intensities and contact times correspond to the required target at every point along every cleaning process.

Cleaning validation and documentation

Through intelligent data processing, Clean Assist enables genuine cleaning validation as well as end-to-end, location-based documentation of the cleaning process. It supports the guided optimization of cleaning cycles and helps to avoid errors resulting in reduced product quality caused by incorrect cleaning. At the same time, cleaners can be trained in a targeted way by means of special practice exercises.

Project information CleanAssist

Cooperation partners: |

ADVITEC Informatik GmbH, WALTER Gerätebau GmbH |

| Project sponsor/Grant authority: | Federal Ministry of Economic Affairs and Climate Action on the basis of a decision by the German Bundestag |

| Grant number: | 16KN082122 |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV