Phthalate containing PVC flooring cannot be recycled by conventional means

Due to the versatility and durability (> 30 years), PVC is commonly used in the construction industry for amongst other things window frames, pipes, and flooring. However, at the end of their lifetime these PVC products pose great challenges for the circular economy.

Old PVC flooring usually contain specific plasticizers that can no longer be used in PVC production today for consumer protection reasons. The processing of PVC flooring for the production of PVC recyclates in virgin material quality therefore requires the separation of plastizisers. The only alternative would otherwise be thermal recovery, which wastes valuable resources.

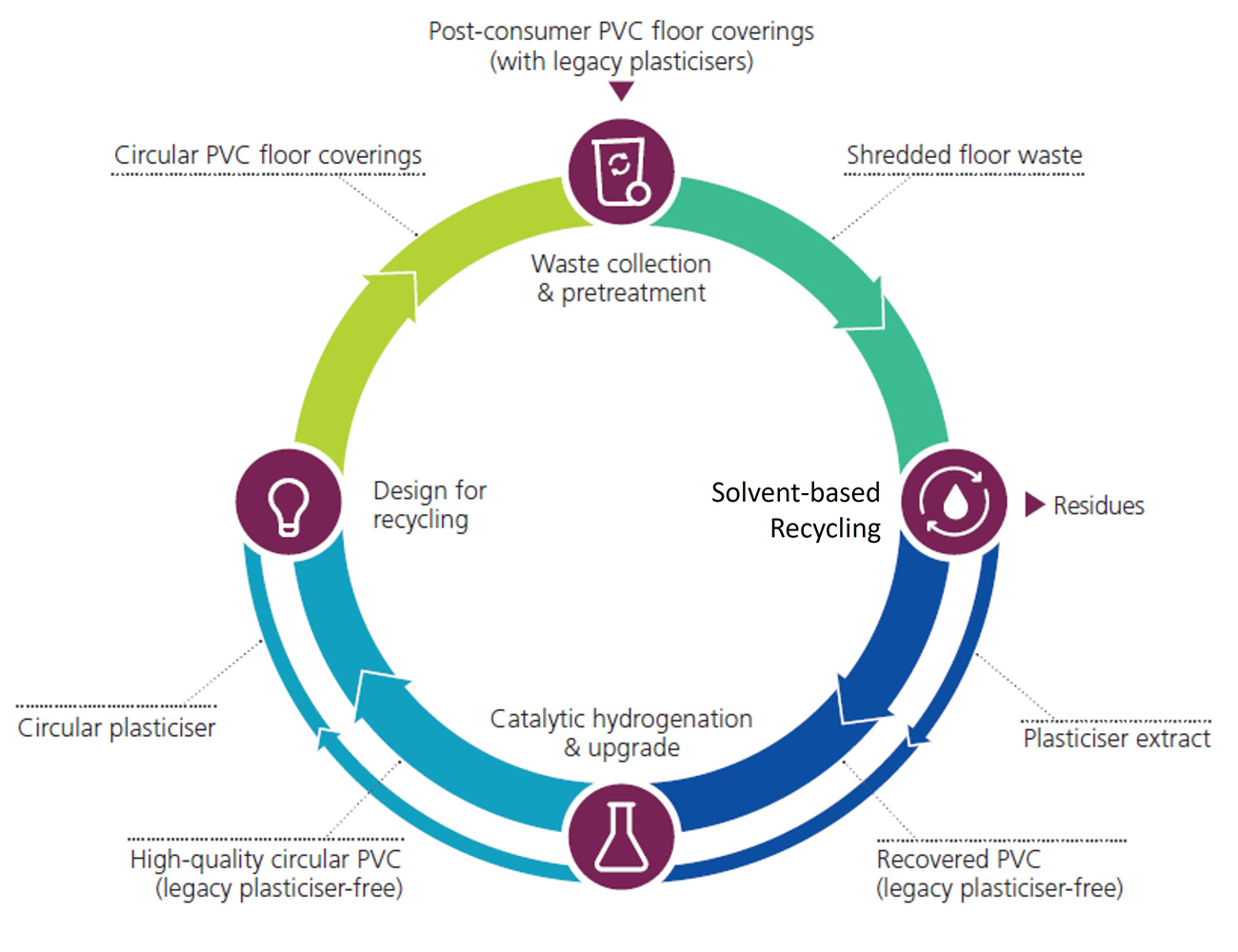

Solvent based process for recycling phthalate containing PVC flooring

The EU-funded “Circular Flooring” project successfully tackled this challenge. The primary aim of the project was to develop innovative recycling processes to recover high-quality PVC from old flooring. Critical phthalate plasticizers were removed from the material and converted into non-critical substances. This approach can reduce the negative environmental impact of PVC waste and promote sustainability in the flooring industry.

As part of the project, the feasibility of recycling PVC floor coverings was successfully demonstrated at a technical scale (TRL 6) using a solvent-based process patented by the Fraunhofer IVV. To facilitate this, a versatile pilot plant for plastics recycling was established at the Fraunhofer IVV premises during the project period. By the end of the project, several hundred kilograms of high-quality PVC recyclates were produced at the plant and successfully utilized by an industrial partner in new floor coverings.

Furthermore, the project demonstrated that the recycling process is economically viable when processing more than 15 kilotons of PVC flooring waste annually. This represents a sustainable and profitable alternative to thermal recycling.

“Circular Flooring” has set a new standard for PVC recycling and added an effective cleaning stage to solvent-based PVC recycling. Its success has the potential to drive change in the industry, encourage other companies to adopt similar recycling technologies and help the industry comply with increasingly stringent regulatory requirements.

The project consortium comprises 11 European companies and research organizations (from Germany, Austria, Belgium, France, and Greece). The Fraunhofer IVV is coordinating the project.

Project term: |

2019 to 2024 |

Project management |

EU, EU Framework Programme for Research and Innovation Horizon 2020 |

Website: |

|

Twitter: |

|

LinkedIn: |

Circular Flooring – Pioneering Recycling Process for PVC Waste |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV