The Fraunhofer IVV in Freising has developed an innovative recycling process for plastics, which allows high quality plastic recyclates to be recovered from plastic waste. Up until now the material recycling of these plastics has not been possible. The waste plastics include plastics from waste electrical and electronic equipment, end-of-life cars, and from the production of technical laminates and composites.

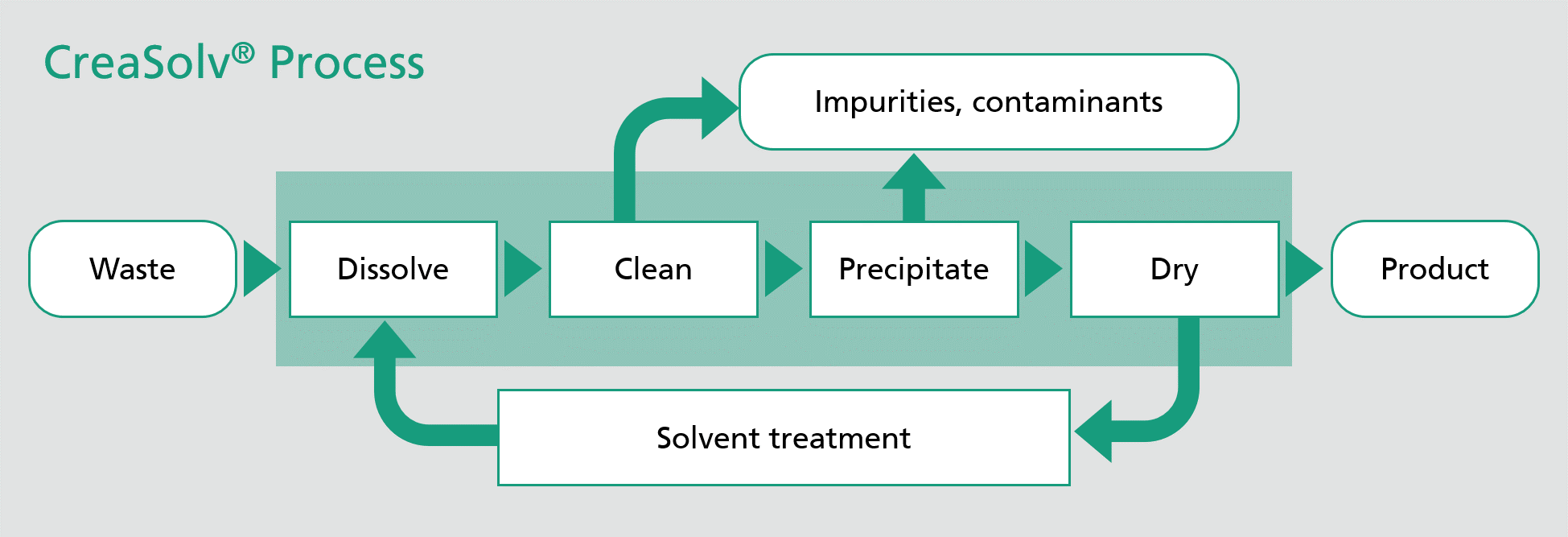

The process involves the following principle: The target polymer is dissolved out of the waste mixture using a selective and technically safe solvent. The resultant polymer solution is then mechanically purified, and if necessary purified by extraction. After drying the purified product and any byproducts and returning the solvent to the cycle, the final product is a high-quality polymer recyclate. The downstream final processing of the products completes the process. The development work was carried out in collaboration with CreaCycle GmbH, Grevenbroich, a specialist developer of hazard symbol free solvent formulations.

In September 2010 a new collaborative project was started: The collection and processing of waste plastics containing contaminants from shredder residues from the processing of waste electrical and electronic equipment and end-of-life cars in Europe, and the production of plastic recyclates that comply with legislation. This will require a larger pilot plant for the process which is suitable for processing contaminated plastics. In order for these polymers to be economically recycled, two development lines must be merged to form one continuous process and the property profiles of the recyclates must be optimized.

This project could substantially advance the use of recyclates, not least because of economic boundary conditions such as the increasing price of oil.

Project term: |

2010 to 2012 |

Project management |

Forschungszentrum Jülich (FZJ) |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV