Material characterization and behavior

Your partner for sustainable packaging solutions

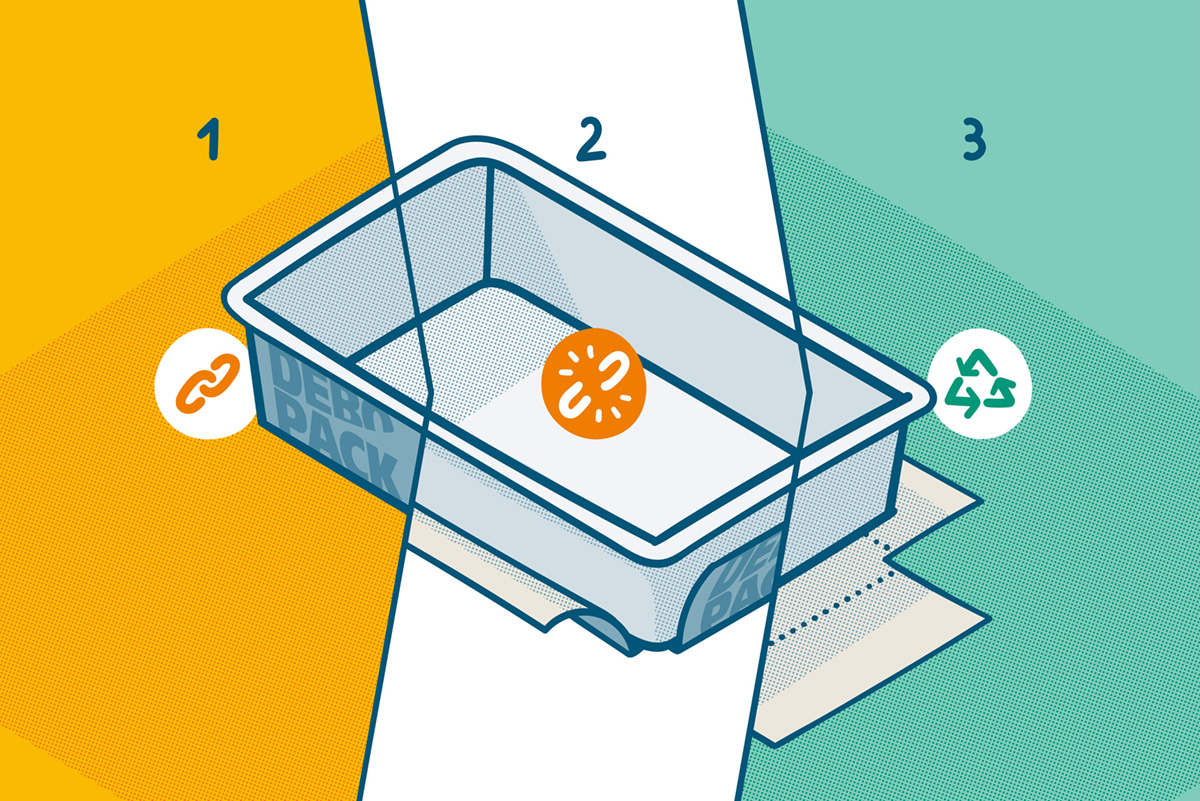

The plastic composites that have been predominantly optimized in recent years are increasingly being replaced by recyclable monomaterials or even bio-based, recycled and fibre-based materials - always with the aim of minimizing material thicknesses in order to conserve resources. This is reinforced by legal requirements and, in some cases, severe fines that must be paid by producers who place products on the market without ensuring that the materials are returned or recycled. The challenges include processing new packaging materials on existing technology. Packaging material breakage, wrinkling or leaking seal seams are only some examples of problems that can be caused by a change of packaging material or even just a change of supplier.

We test the processability of your materials in advance by simulating processes such as sealing, forming on the forming shoulder and transporting the packaging material through the packaging machine - on production machines and on specially designed test rigs.

We support our partners from the initial idea through to series production!

Material simulation and modeling

Are you also interested in which packaging can be produced from alternative materials? Do you want to process new materials on your systems without time-consuming and expensive tests? We support you with advanced material simulation and modelling by virtually testing and optimizing your materials - even before packaging production!

You can ensure that even materials with recycled content can be predicted in your processing with simulation methods. With our comprehensive expertise, we provide you with recommendations for packaging selection as well as options for process and tool optimization.

Digital simulation makes it possible to test materials under real conditions. For example, you receive answers to the question of how your packaging material will behave under extreme temperatures, moisture or mechanical stress. This is not only interesting for applications in the food industry, other sectors such as the cosmetics and electronics industries also benefit from customized solutions. The finite element method (FEM) for structural analysis as well as the computational fluid dynamics (CFD) method for flow analysis are used. Depending on the application, the Fraunhofer experts also use specific software solutions such as LS-DYNA, Ansys Workbench or Abaqus.

You can produce the packaging of tomorrow with our models.

Material and processing behavior

Do you want to specifically counteract the causes of print mark displacement, wrinkling and leaking seal seams during pouch production? Does paper forming, e.g. during the deep drawing process or thermoforming process, not work satisfactorily? We will find the right solution with our expertise.

Many of today's established methods for material characterization have one thing in common: they are not close enough to the real process. We identify, characterize and evaluate all relevant material and process parameters using our specially developed test technology under process-related stresses (normal force, relative speed, tool temperature, material moisture) and derive recommendations for your process.

For this we use and develop methods for the simulation of complex load situations within suitable substitute tests and on machines, equipped with special measurement technologies for this purpose within our unique »Test Center Processing Behavior«.

For a successful transition to more sustainable materials, we support you in targeted material development and optimization, the development of suitable e.g. bio-based coatings and provide recommendations for adapting and optimizing your processes.

We increase your production efficiency by analyzing and characterizing your materials!

Material evaluation, comparison and selection

Would you like to use more sustainable packaging materials and improve the recyclability of your products in accordance withthe objectives of the PPWR? Are your processes being converted to alternative, fiber- or bio-based materials and are you looking for a competent partner? The Fraunhofer IVV supports you in further developing materials and optimizing their machinability.

A professionally grounded knowledge of material properties such as barrier effect, mechanical resilience, functionality and industrial processing behavior up to recyclability is crucial for applications in the food sector, medicine, pharmacy or cosmetics. We support you from the point of the material analysis stage and test your materials - whether bioplastics, papers, nonwovens, highly functional barrier and sealing layers or recyclates - for their suitability under real processing conditions.

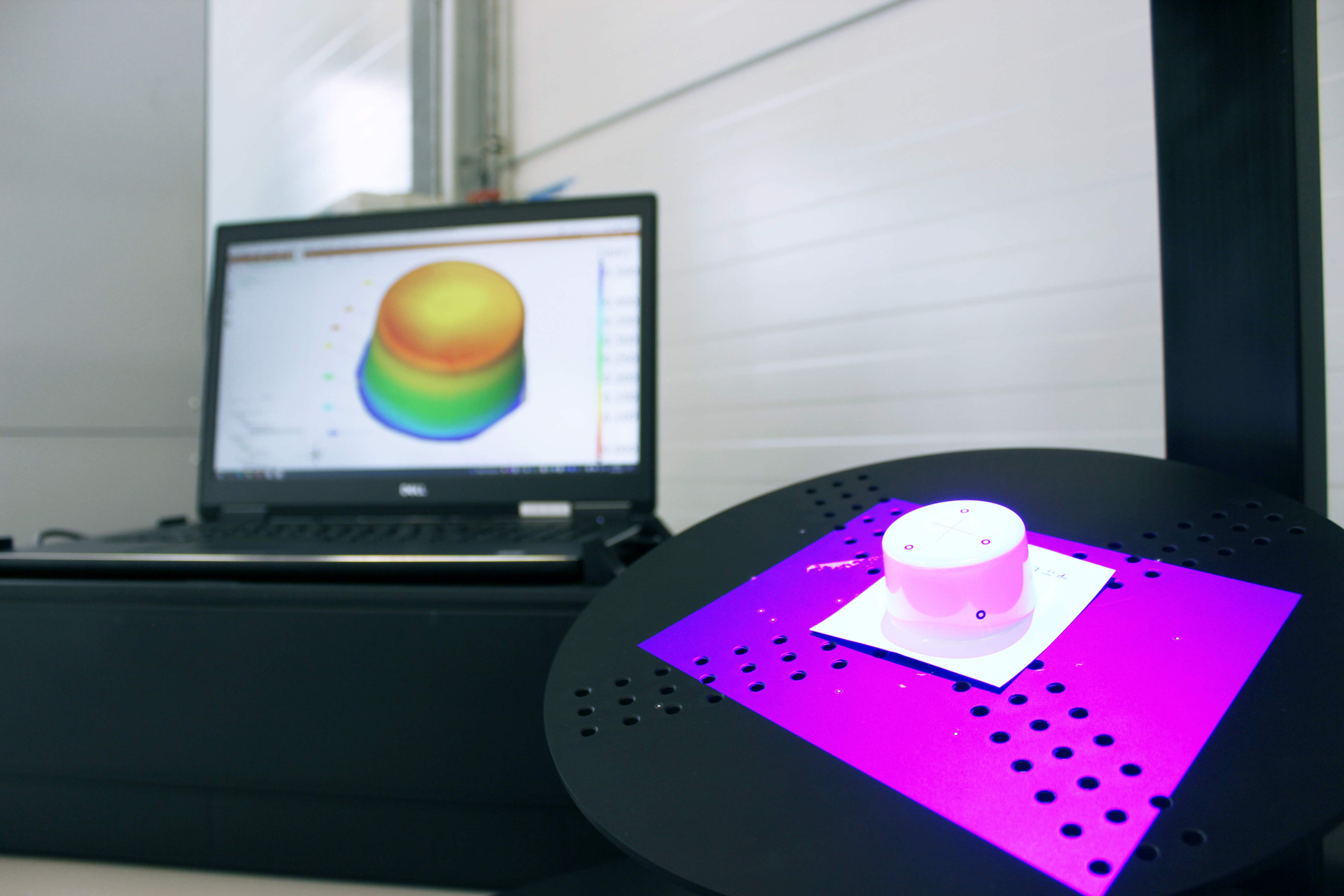

In addition to standardized characterization methods such as stress-strain and bending stiffness measurement, we also use practical, in-house developed test methods, e.g. to determine the dynamic coefficient of friction (VDMA standard sheet 34171) and use optical measuring systems such as the oWTP scanner for early fault detection in the web run behaviour or ARAMIS for non-contact recording of strains, displacements, speeds/accelerations or rotations. In this way, we ensure processing quality and optimize the use of materials. We also offer comprehensive seam inspections to evaluate the seam strength, tightness and melt flow. In our »Test Center Processing Behavior«, we support you from the point of material testing to the finished packaging solution.

We support you in material development and reduce your development times.

Packaging testing

You place high demands on your packaging: These must not only reliably ensure product protection, but also efficiently support packaging, transportation and storage processes and must fulfill an important communication function at the same time. We check for you whether your packaging meets these requirements.

The central task is to protect the contents - such as foodstuffs - from external influences and to protect the environment from hazardous substances. The prerequisites for this are impermeability, stability, suitability for use, suitable geometry and recyclability. In our technical center, we test whether materials and packaging meet functional requirements. To do this, we use standardized leak tests (e.g. leak tests, vacuum or water bath methods according to ASTM D3078, DIN 55508-5, ASTM F2338, ASTM F3039) and microscopic analyses to investigate the causes of leaks. The mechanical strength of packaging materials, packagings or sealing seams is also comprehensively tested (e. g. Material Strength: DIN-EN-ISO 527 T3-5, Seam strength: DIN 55529, ASTM F88/F88M-21, Adhesive Peel Resistance, T-Peel Test: ASTM D1876). Other methods such as 3D detection or wall thickness measurement are used to analyze and evaluate the emptying ability, stackability and appearance.

Customer acceptance is also crucial: with the Pack Peel Scan (DIN SPEC 91441, DIN 55409-1/-2, ISO 17480), we record the real opening forces / peel forces - both in the laboratory and in production - including integration into assistance systems for seal seam analysis.

We develop practical test methods and are your active partner in standardization work.

Packaging development

Product protection, simple and cost-effective manufacturability with low resource consumption and good recyclability are very important for you? With our comprehensive expertise in packaging technology, we can help you solve these challenges.

Successful new packaging developments or optimizations take into account all relevant aspects of the packaging life cycle - always in accordance with the objectives of the current PPWR. These include the targeted use of recyclates, bio-based packaging materials, improved sortability and recyclability as well as the avoidance of packaging waste, e.g. by using less plastic. Particularly in mass production, for example in the food industry, the smallest packaging adaptations can result in major material and energy savings - with high requirements for technical feasibility at the same time. We analyze your packaging task, structure the requirements and systematically develop solutions. This includes the production and testing of prototypes, the evaluation of technical feasibility and the consideration of legal requirements and relevant regulations.

We use our production machines and test rigs for testing new packaging solutions close to industrial practice and focussedon flexible or rigid packaging variants. 3D printing also supports development by producing prototypes of components such as closures. This data can also be efficiently integrated into digital services and tools and made available to your packaging developers..

We evaluate new packaging in terms of food approval, gas permeability, life cycle analysis (LCA) and recyclability. Ultimately, consumer acceptance also has a significant influence on the market success of the product and packaging.

Design from recycling or reusable packaging? We rethink your packaging solutions!

Sensor development and test methods for material analysis

Do you expect stable processes, reliable data and efficient use of resources? We provide and develop the right measurement technology!

The development and integration of sensors for quality monitoring and the development of suitable test methods improve process stability and reduce machine downtimes, rejects and material and energy losses. Inline monitoring enables targeted and intelligent process control.

The reduced use of packaging materials, new fiber-based materials and efficient processes require precise knowledge and exact compliance with process parameters. The Fraunhofer IVV Dresden is developing suitable measurement methods and testing techniques for this purpose, including self-sufficient test rigs for determining material and processing properties as well as validated measurement technologies for industrial use.

For example, the temperature is a critical parameter in heat contact seals processes. Together with the Fraunhofer IWM in Freiburg, a thin-film measuring system was developed that records temperature curves with high resolution - more precisely than previous technologies. This is the basis for future real-time control with highly dynamic heating systems as well as for AI-based process analyses and seamless traceability. The temperature profile shows the heat flow from the tool into the packaging material and allows conclusions about folds, seam contamination and leaks.

We also support you in optimizing the machinability of your materials, for example by measuring the web tension distribution inline with our non-contact oWTP scanner. We are also working with partners on solutions for inline coating thickness detection to ensure product protection and sealability.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV