Efficiency and Sustainability Analyses

Measurement of Efficiency and Sustainability Indicators

The complex and automated production of food, non-food, healthcare, and other products places high demands on machine systems, personnel, and value chains. At the same time, regulatory reporting obligations in the field of sustainability, such as the Corporate Sustainability Reporting Directive (CSRD), are increasing. As a plant operator or machine manufacturer, we support you in measuring the efficiency and resource consumption of your production, cleaning, and disinfection processes in a time-, product-, and machine-specific manner to identify optimization potential.

Fraunhofer IVV provides automated tools to record downtime to calculate equipment effectiveness, availability, and performance, as well as measuring resource consumption (energy, water, chemicals). We combine the data acquisition with over 15 years of experience in numerous analyses, along with our methodological process expertise, to identify both technical and organizational improvement opportunities.

Our market expertise and independent perspective enable us to deliver data-driven insights into your production, cleaning, and disinfection processes. This solid data foundation enables you to evaluate and optimize the profitability of your production and side processes while meeting regulatory reporting requirements.

Measure resource consumption and equipment efficiency with us – benefit from a high-resolution data acquisition system and cross-industry process expertise!

Recording of Overall Equipment Effectiveness / OEE

Do you know the efficiency, time, and performance losses of your machines and equipment?

With our data acquisition system and real-time evaluation methods, we provide you with the key indicators needed to describe the operating behavior of your machines and production lines, along with precise root causes of malfunctions for further optimization.

For over 15 years we have been conducting machine analyses and have the expertise and technical tools to record the necessary KPIs for determining equipment effectiveness.

Smooth production processes are critical to a company’s profitability. Metrics such as efficiency, technical and organizational availability, quality output, and output losses provide insights into production efficiency and stability. Our »VERA« data acquisition system collects reliable, synchronized sensor-based data from your machine system with a resolution of 1 second. In addition, our scientific staff have the methodological expertise to identify and assess disturbance causes. Based on the analysis, we determine standardized, significant KPIs in real time according to DIN EN 415-11.

To technically optimize your machine system and production processes, we use sensors and statistical methods to quantify the impact of process variations on operating behavior. The aim of the analysis is to optimize machine configuration and settings in order to increase robustness.

The results of a neutral machine and equipment analysis allow you to make well-founded decisions in the context of machine acceptance testing or production optimization, and to eliminate root causes of malfunctions sustainably.

As an independent partner, we determine the effectiveness of your equipment and identify optimization potential by detecting and quantifying causes of disturbances.

Sustainability Assessment of Production Processes

Do you want to know the energy and media consumption of your production?

Do you need measurement data on the consumption of electricity, packaging material, compressed air, water, cleaning agents, or disinfectants for reporting or production optimization?

We have the expertise and the technical equipment to record the data independently for your products, systems, and machines over specific time periods.

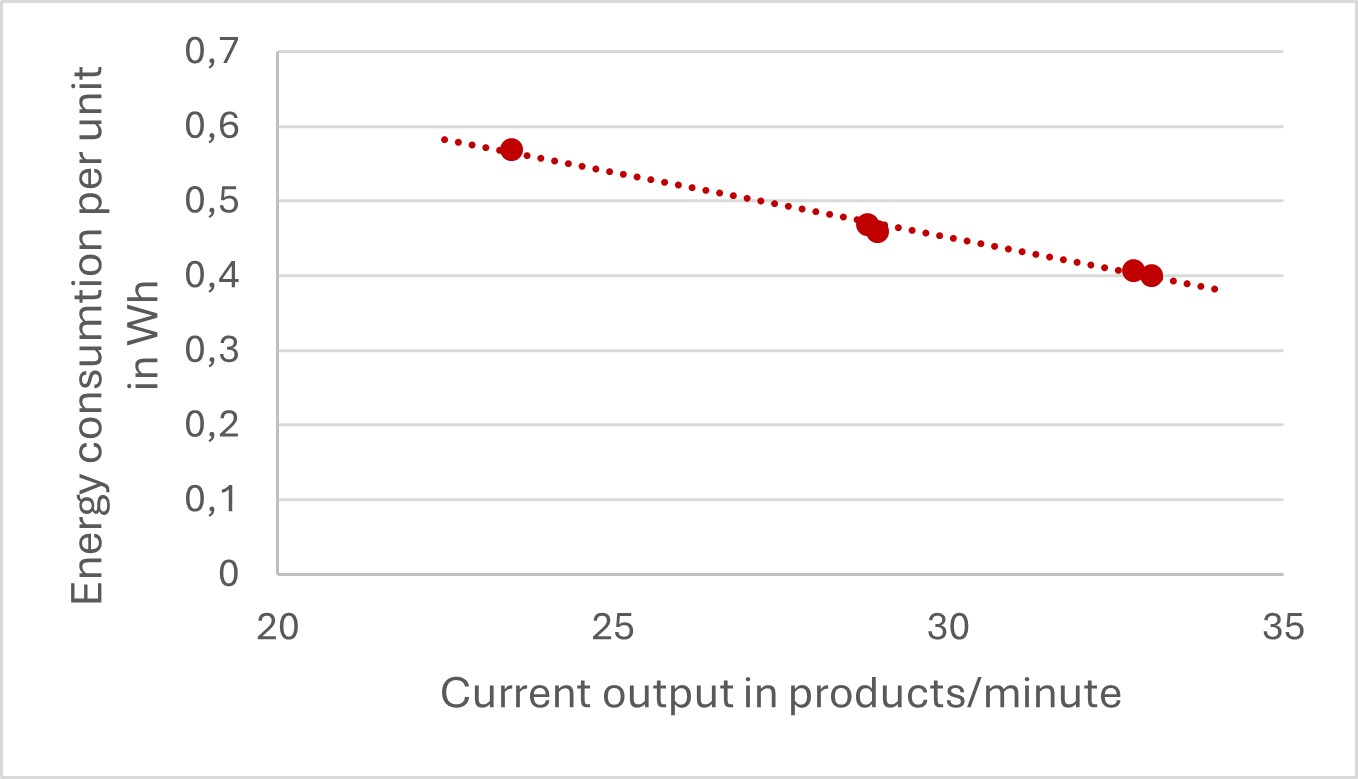

We combine the measurement of energy and media consumption with the operating states of your processing or packaging machine in accordance with DIN EN 415-11. This enables us to determine the consumption data according to VDMA Standard Sheet 9751:2019-03. The sensor technology we use to measure energy and media consumption (compressed air, water, cleaning agents and disinfectants) allows resolutions down to one second and operates interference-free, independently of your system. In addition, we can also record the consumption of packaging material and product, as well as account for output losses. These data allow product-, machine-, or time-specific evaluations.

With the measurements, you can increase the efficiency of your production and cleaning and disinfection processes. By reducing or targeting the control of energy and media consumption, you can optimize production and reduce your carbon footprint.

Together with you, we also identify technical and organizational optimization potential and propose alternative solutions to improve the sustainability of your systems and processes. At the same time, the measurement data provide a sound basis—compared to databases—for determining further key figures such as Life Cycle Analysis (LCA). This way, we provide you with real data for required sustainability reporting, such as the Corporate Sustainability Reporting Directive (CSRD) or the Energy Efficiency Act.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV