Packaging development pilot plant

Manufacture, processing, and conversion of polymers

Pilot plant for packaging solutions: Efficient development and material testing

With our technical center, we are happy to support you in the product development of web-shaped materials. We offer you our systems for thermoplastic processing, coating and vapor deposition at fixed daily rates.

This gives you the opportunity to carry out product optimization on a pilot plant scale with low material input. While you test new materials and material combinations, your in-house production can continue. This allows you to significantly reduce your own development costs.

Your benefits

- Development time and costs up to industrial implementation in production are reduced

- Production of new materials or material combinations on a pilot scale, with initial machine-compatible test quantities on rolls for application trials on your systems

- Iterative optimization of new materials with regard to their properties and processing by our in-house test laboratory

- Your production facilities remain efficient by outsourcing initial machine trials

- You benefit from our expertise and many years of experience in the development and evaluation of packaging materials

Processing thermoplastic materials

On our pilot plants, we determine technical feasibility and individual processing and functional properties for you in a time and cost-saving manner before they are optimized on industrial production systems.

We offer you processing tests for plastics on a scale from a minimum of 1 kg up to several 100 kg. The following are manufactured:

- Individual polymer compounds (bio-based, containing recycled materials, additive-based)

- Monomaterials, also bio-based

- Materials containing recyclate or fibers

- Multi-materials according to customer requirements

- Injection molded test specimens

- Thermoformed parts

Our packaging test laboratory is equipped with all the measuring equipment required for the iterative characterization of raw materials, initial material samples and their application properties.

Thermoplastic material processing in our pilot plant

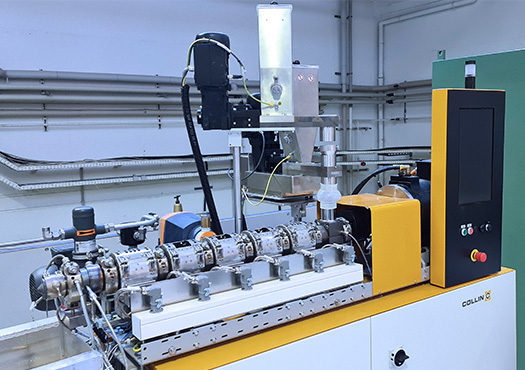

Co-rotating twin-screw extruder

Co-rotating twin-screw extruder

Technical details |

Production of polymer compounds (e.g. use of recycled materials) |

Dosage |

Up to three solid dosages and one liquid dosage |

Screw |

25 mm |

Speed |

Maximum 800 rpm |

Temperature |

Maximum 400 °C |

Throughput |

Maximum 15 kg/h |

Outgassing |

Atmospheric & vacuum degassing |

- Twin-screw extruder 50 kg/day

- Smallest quantity processing possible >1kg

- With vacuum pump unit specially developed for mechanical recycling - degassing of residual moisture and solvents

- Additives can be added - liquid and solid additives (e.g. colorants, antioxidants, fibers, etc.)

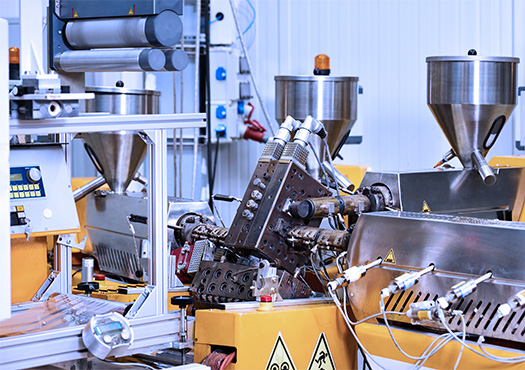

7-layer coextrusion line

7-layer coextrusion line

Extrusion coating and extrusion laminations possible on various materials.

| Technical details | Flat film line with up to 7 layers |

| Materials | Processing of up to 4 different polymers |

| Dye width | 300 mm |

| Film width | 250 mm |

| Throughput | 1 kg/h bis 15 kg/h |

| Film thickness range | 20 μm to 1.5 mm (sensor-supported inline monitoring of the film thickness) |

| Winding speed |

Up to 16 m/min |

Injection molding machine

Injection molding machine

| Technical details | Clamping force of 350 kN |

| Materials | Thermoplastics bio- and petrochemical-based, with and without fibers, various bio-based polymer |

| Process details |

Integrated, individually adjustable drying possible |

| Injection mold form |

|

Laboratory thermoforming

Laboratory thermoforming system for the production of deep-drawn parts

| Technical details | Maximum heat output of 3.9 kW |

Maximum pressure of 8 bar |

|

Bowl shape 120x120x30 mm |

Coating and vapor deposition of web-shaped materials

The constant reduction of materials, costs and environmental impact in terms of sustainability and recyclability is leading to new solutions in the field of barriers. In particular, the combination of coating/laminating and vacuum evaporation delivers good results. With our systems, we enable you to take the important step between laboratory scale and production in a time and cost-saving manner. Your new materials are tested and combined before the production phase.

Take advantage of the opportunity to test alternative application processes, clarify efficient process parameters and produce samples for further application tests. For this purpose, we are at your side within the scope of smaller orders, in bilateral R&D projects, but also in cooperation in larger, partly publicly funded projects.

Our pilot plants for web-shaped materials

Lacquering and laminating system

Lacquering and laminating system

| Film dimensions | Film width: up to 480 mm Application width: up to 460 mm Film thickness: by arrangement |

| Typical base materials | Plastic films, vacuum-coated films, biodegradable polymers, paper and cardboard, aluminum films, others on request |

| Coating | Coating protected by enclosure Solvent-based coating materials: low-viscosity paints, adhesives, high-viscosity biopolymers (e.g. starch), protein-based systems (e.g. caseins) and modified biopolymers |

| Web speed | Max. 30m/min |

| Application method | Slot die coating Anilox rollers for low-viscosity coating systems Temperature-controlled roller mill up to 80 °C |

| Corona unit | Corona treatment of non-conductive films, corona power adjustable from 0.15 kW to 1.5 kW |

| Laminating unit | 350 N/cm per 500 mm belt width; temperature control up to 80 °C |

| Special film guide | Functional layer can be transported without contact after coating; separate servo-controlled rewinding |

| Drying and cross-linking | IR, UV, convection drying |

Vacuum coil coating system

Vacuum coil coating system (with electron beam evaporator)

| Film dimensions | Film width: 280 mm Film length: up to 100 m (for Al approx. 30 m for SiOx 50-100 m) |

| Typical base materials | Paper and various plastic films such as polypropylene (BOPP), polyethylene terephthalate (PET), polyamide (nylon) or polyimide (Kapton), but also films made from bio-based polymers (e.g. polylactic acid (PLA)) |

| Coatings | Vapor deposition with metals (e.g. Al) Oxides (e.g. SiOx and their mixtures) |

| Web speed | 1 - 10 m/min |

| Evaporation source | Electron beam evaporator |

| Inline measurements | Quartz layer thickness monitor |

| Application examples | Gasbarrier layer Al, SiOx Optical coatings: Al,Ag |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV