EHEDG Cleanability Test for Open Systems

Authorized Test Laboratory

We offer extensive expertise and state-of-the-art technical equipment in the field of cleaning technologies.

At our Pilot Plant Cleaning Technologies, a wide range of industry-relevant cleaning methods as well as innovative technologies for reliable contamination detection are available.

This combination of expertise and technical resources enables precise and reliable execution of cleanability tests and qualifies Fraunhofer IVV as an authorized test laboratory for certifications in accordance with EHEDG standards.

Product Safety and Consumer Protection Through Certified Cleanability Tests

Hygienic Design as the Key

The hygienic design of machines, equipment, and components is a key factor for efficient cleaning and disinfection. It directly impacts not only product safety and consumer protection but also the resources required for cleaning.

The fundamental principle of cleanability applies: all surfaces and machine elements that come into contact with the product must be effectively and efficiently cleanable.

Certification According to EHEDG Standards – Now also for Open Systems

The European Hygienic Engineering & Design Group (EHEDG) is dedicated to the practical application of the hygienic design concept. In addition to publishing guidelines, EHEDG develops specific cleanability tests that enable the assessment of the fundamental cleanability of equipment and components within a certification process.

Until recently, cleanability certification, in cases where testing was required, was limited to closed systems such as pipelines and pumps. In response to increasing demands and requests from industry, Fraunhofer IVV - working in close collaboration with EHEDG and two European test laboratories - has led to the development of a new cleanability test specifically for open systems (Doc. 57). This test is particularly beneficial for hygiene-critical industries such as food production, pharmaceuticals, and cosmetics.

Test Procedure

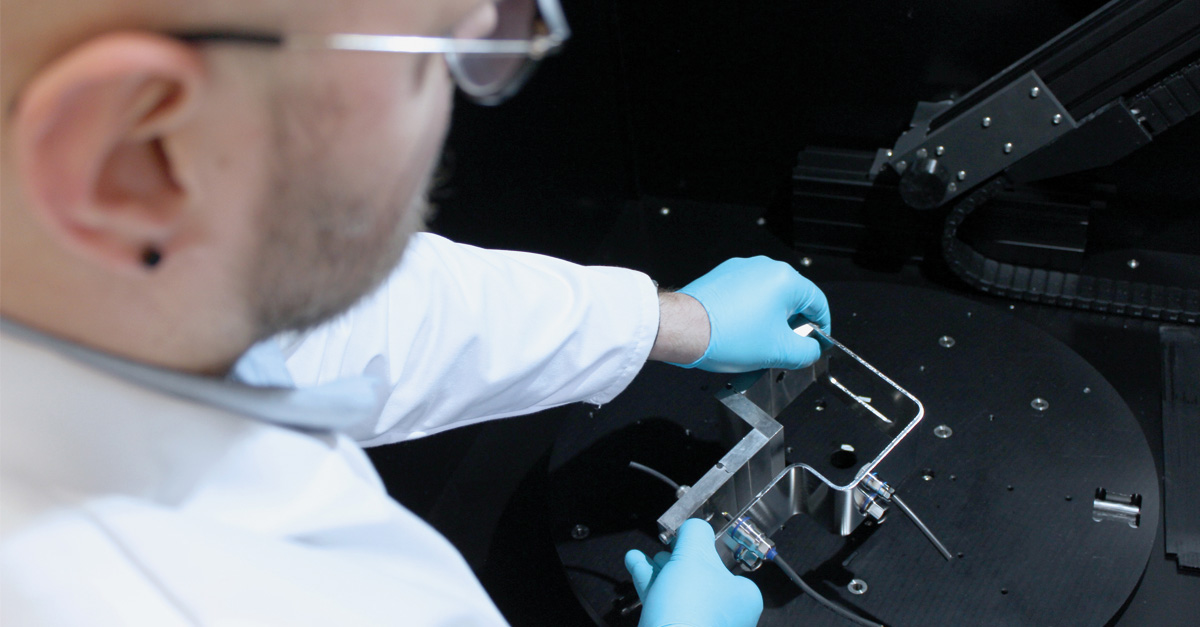

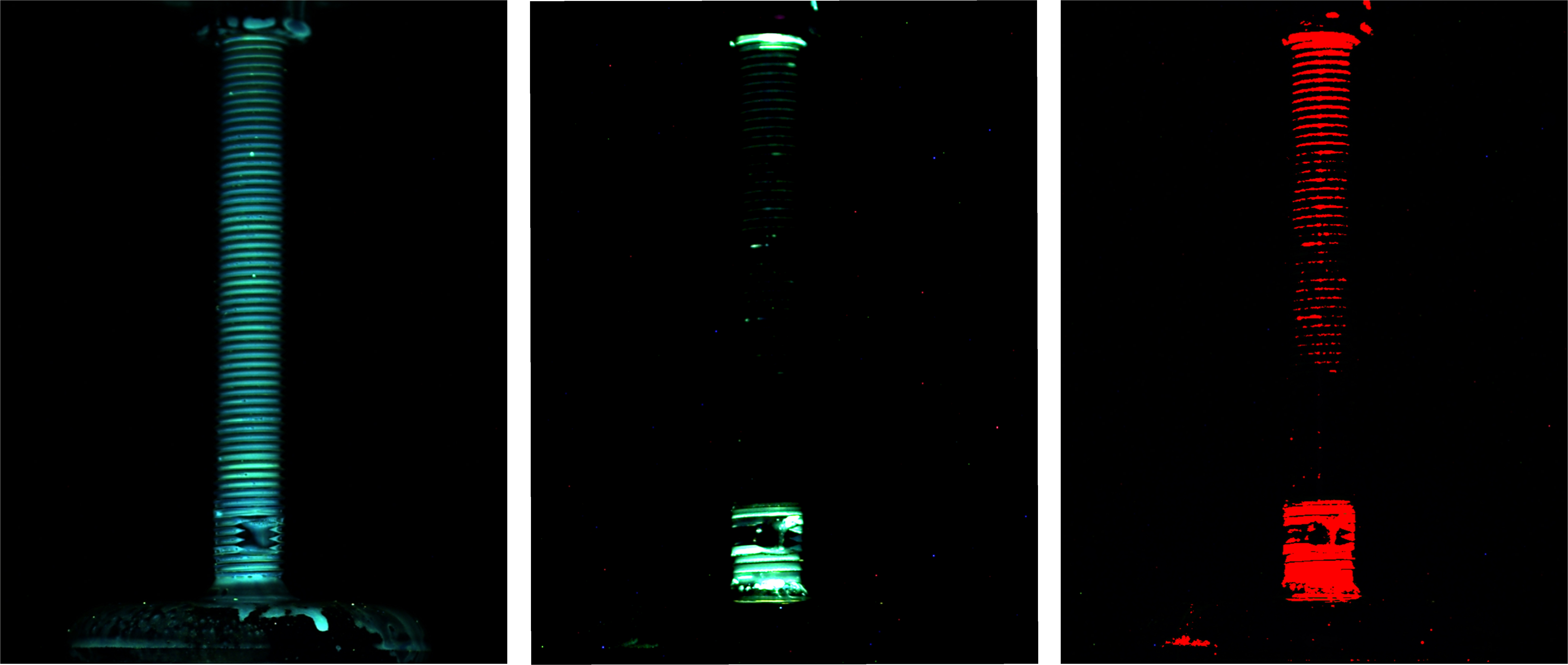

The multi-step test begins with complete disassembly, cleaning, drying, and reassembly of the components. To ensure realistic conditions, a condensed-milk-based model soil with optical tracers is applied. Cleaning is carried out by an industrial robot using spray technology, ensuring reproducible test execution.

Additionally, optical detection with UV light enables precise evaluation of cleaning results by making the fluorescence properties of the contamination visible.

Furter Information

| Cooperation partners: | EHEDG (European Hygienic Engineering & Design Group), actalia, ainia |

The New EHEDG Cleanability Test on Video

With this new test, equipment and component manufacturers can evaluate their designs against upcoming EHEDG standards early in the development process.

Our expert, Dr. Enrico Fuchs, presents the test:

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV