Immediate state monitoring in the system

Due to their inaccessibility, closed production lines in hygiene-critical areas such as the food, cosmetics or pharmaceutical industries are still cleaned by oversized cleaning-in-place (CIP) processes designed for the worst-case scenario. In order to support companies in the transition toward demand-oriented, resource-saving cleaning processes, a sensor solution for the detection of viscous contamination in closed systems has been developed in the “SensoRein” research project.

For the first time, this makes it possible to measure the contamination state during the fouling and cleaning processes directly and without alternative operations. What’s more, reliable conclusions about the actual cleaning requirements and success of the cleaning process can also be drawn.

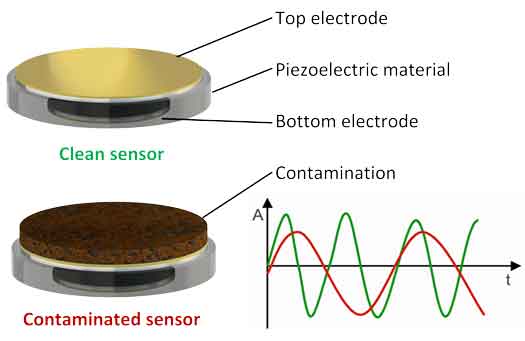

Oscillating quartz technology for inline cleaning monitoring

The quartz-based thickness shear mode resonator Co-Control-QCM uses the inverse piezoelectric effect. In doing so, it obtains the information about the dirt layer on the surface from the specific changes in the characteristics of its vibration behavior. With the aid of a special evaluation algorithm, these changes in the natural frequency can be used to signal that the cleaning target has been achieved.

Demand-oriented process control and cleaning times

As the sensor has comparable properties to the surfaces to be cleaned in the pipelines, intelligent positioning of the sensors in the pipelines to be cleaned enables demand-oriented process control, while the use of resources and cleaning times are always adapted to requirements. The cost-effective sensor solution can be retrofitted into existing systems with little effort.

Project information Co-Contro-QCM

Cooperation partners: |

Verband Deutscher Maschinen- und Anlagenbau e. V. (VDMA), Institute for Chemical and Thermal Process Engineering at TU Braunschweig, Fraunhofer IPM, Fraunhofer IST and Fraunhofer IFAM |

| Project sponsor/Grant authority: | Federal Ministry of Food and Agriculture based on a resolution of the German Bundestag |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV