New materials – new joining challenges

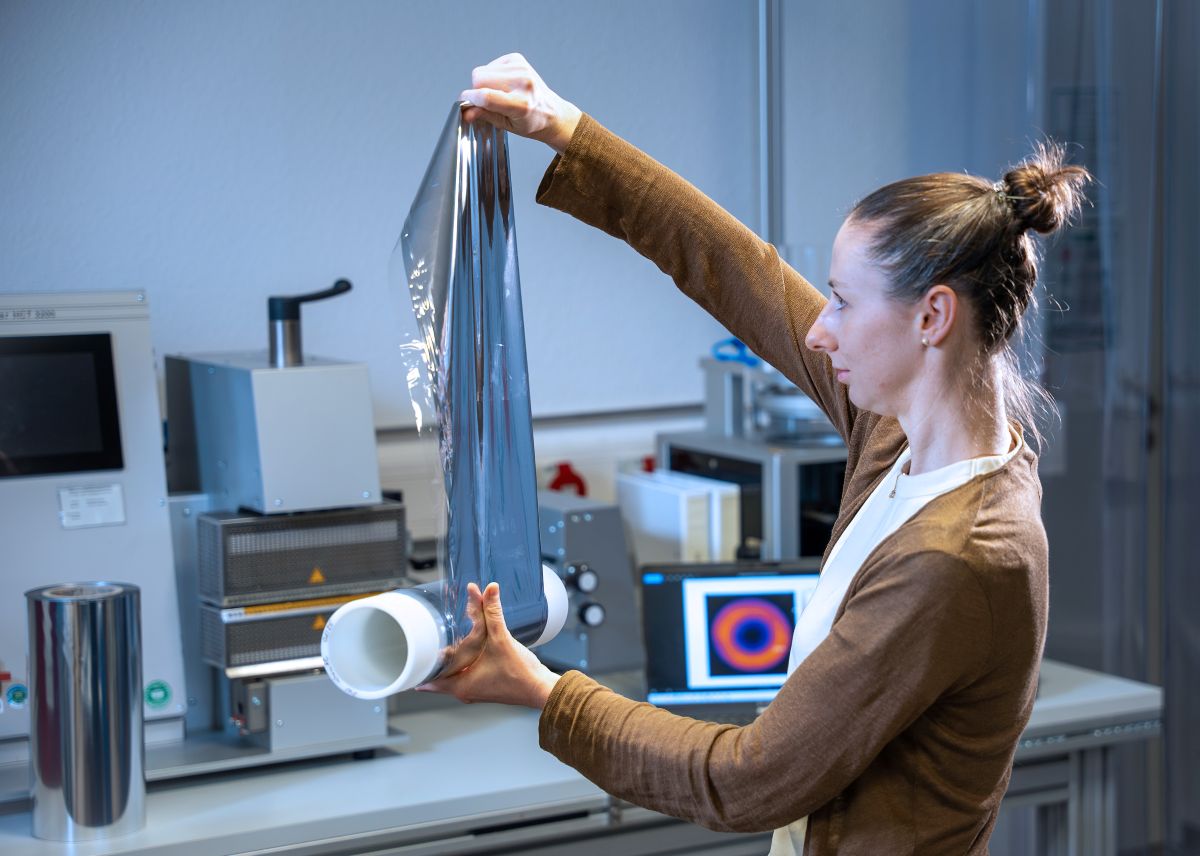

The demand for recyclable plastic packaging continues to grow, driven by regulatory requirements and increasing environmental awareness among consumers.

Innovative, easily recyclable mono-material film systems offer an alternative to established, non-recyclable laminates, but they also bring new challenges: Conventional heat-sealing methods struggle because the heat must be conducted from the outside into the sealing area. This can lead to complete melting of the seam zone and reduced process reliability..

Efficient, gentle, reliable: induction sealing for secure seams

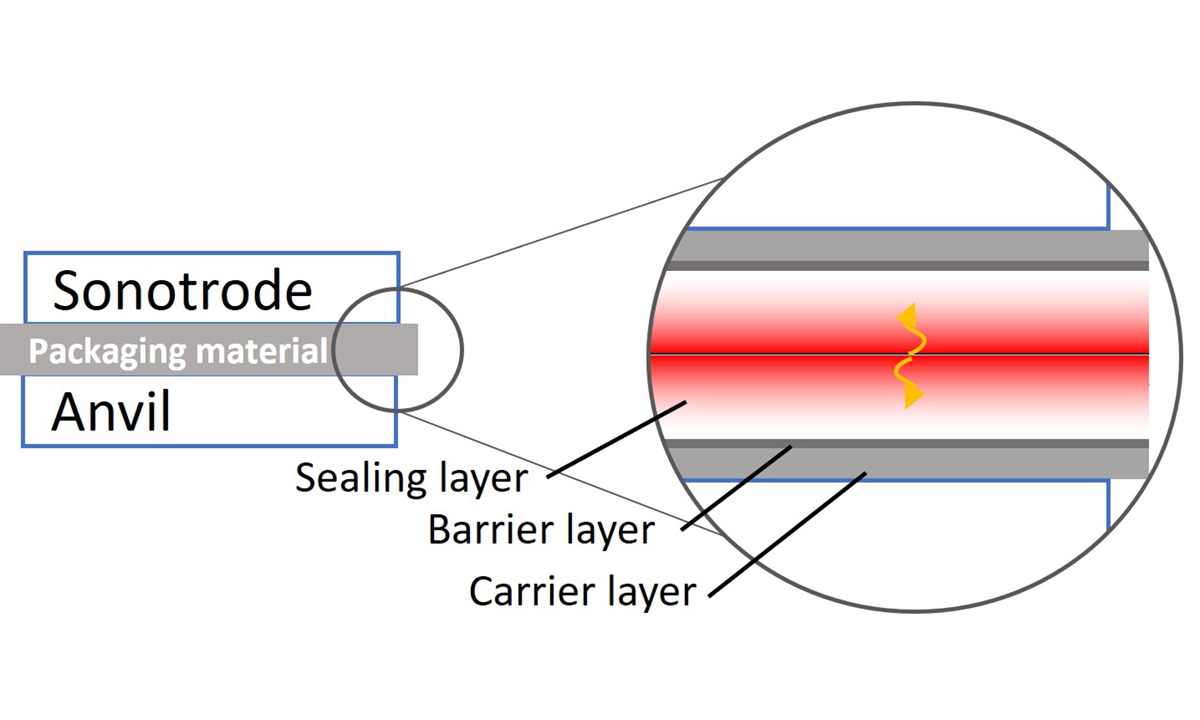

Induction sealing offers a promising alternative to classical heat-sealing. In this process, energy is applied directly to a conductive layer (aluminum) and converted directly into heat where it is needed. This ensures that the zone is heated exactly and efficiently, without unnecessary thermal stress - particularly important for temperature-sensitive products such as food.

Targeted heating at the sealing layer allows for short sealing times, while active seam cooling immediately after heating improves seam quality, and particularly the mechanical strength of the seams during packaging..

Minimal aluminum – maximum seam quality and recyclability

Extremely thin aluminum layers from the metallization process are sufficient to reliably heat the sealing zone. This saves material and enhances recyclability.

In the "mInimAL" research project, the necessary minimum aluminum layer thickness was determined to be between 30–80 nm - well below 1% of the film mass. These ultra-thin layers are sufficient to generate the required process heat while ensuring the materials comply with the standards for mono-material films. Different film constructions were compared for their suitability for induction sealing, ensuring that the thin aluminum layer remains intact during processing while achieving efficient heating of the sealing layer.

Adapting the process for pouch packaging

Up to now, induction sealing has just been applied in industry for sealing round containers with laminate films containing aluminum layers of 5 µm or more (so-called “cap sealing”).

One project goal was to adapt this established process for elongated seam geometries used in pouch packaging. A lab demonstrator was developed to determine the required aluminum layer thickness as well as the optimal processing and setup parameters for induction heating and joining of mono-material films. This laid the groundwork for expanding the industrial application of induction sealing - from the proven cap sealing process to recyclable pouch packaging.

Do you have any questions or would you like more information about our research project? Feel free to contact us!

Further project information

| Project duration | 11/2022 until 5/2025 |

| IGF funding code | 01IF22673N |

| Project sponsor/Grant authority: | BMWE via IVLV e.V. |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV