Surrogates for Aspergillus sp. for sterilization tests

Surface sterilization protects consumers and products

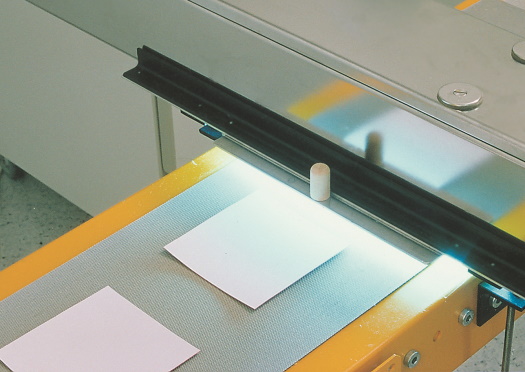

The sterilization of surfaces is vital in many areas of public life and industry in order to safeguard the health of people and to ensure hygienic and safe production processes. Hygienic surfaces are absolutely essential, for example, in the food and pharmaceutical industries and also in public means of transport and public facilities such as washrooms, to name but a few areas. A wide variety of surfaces on objects as diverse as packaging materials, pipes, aseptic packaging machinery, conveyor belts, food products, surgical instruments, walls, door handles, handholds, and touchpads are sterilized using a range of methods on different scales. For example, each year more than one hundred thousand square kilometers of food packaging materials are sterilized in order to protect products from spoiling and to safeguard the health of consumers. This demonstrates the importance and widespread use of surface sterilization.

UV-based sterilization methods are effective and favorable in cost

The methods that are used for surface sterilization are as varied as the applications. Fundamentally, the methods can be differentiated into thermal, chemical, and physical processes. UV radiation based methods are an important and widely used approach for sterilization using relatively simple and in some cases inexpensive equipment without the need for wet chemicals. The group of physical surface sterilization methods includes a number of established methods such as low pressure and medium pressure lamps as well as recent developments such as flash technologies, UV LEDs, and others.

Quantification and validation using Challenge Tests

In order to quantify the antimicrobial effect of different sterilization methods one uses so-called Challenge Tests. Test microorganisms are used here to measure the efficiency of the methods. Challenge Tests are relatively complex procedures but are necessary for a variety of reasons. Indeed, UV radiation is difficult to quantitatively measure in industrial situations and external boundary conditions such as reflection, scatter, shadowing, humidity, etc. and the effect of such on the sterilization efficiency cannot be estimated. Additionally, the geometries of the objects being sterilized and the materials they are made of have a major effect on the microbiological effect of the radiation.

Such Challenge Tests are, for example, also recommended by the VDMA for the microbiological validation of hygienic filling plants for food products (e.g. VDMA FS NuV no. 10; 2016).

The results of such validations are naturally dependent on the resistance of the test organisms and so the latter must be precisely defined. For UV based methods, spores of mold fungi of Aspergillus niger (DSM 1957), and in particular Aspergillus brasiliensis (DSM 1988), have been used in Europe as test organisms for a long time.

Research on new test germs for industrial plants

In 2016, Aspergillus brasiliensis DSM 1988, previously recommended by VDMA as a bioindicator for microbiological validation of the effectiveness of UV-based disinfection processes, was upgraded from risk level 1 to risk level 2 in the "Technical Rules for Biological Agents (TRBA 460)". Since then, it is no longer permitted to work with this mold and its spores outside of approved laboratories and thus it is impossible to use this germ on site, on industrial equipment as a test germ.

The search for an adequate surrogate germ for Aspergillus brasiliensis DSM 1988 was the focus of this project.

Identification of surrogates for Aspergillus species

As part of the project, a comprehensive literature search and an extensive resistance screening were initially carried out with the aim of identifying a selection of potentially suitable candidates. Cultures of selected molds and bacterial strains were prepared under defined conditions and inactivation kinetics were developed for resistance determination using UV-C lamps (low-pressure and medium-pressure lamps) and a xenon flash lamp.

In addition, further aspects relevant to practice were scientifically investigated and evaluated in the project:

- Storage properties of surrogate germs in suspension and as bioindicators before and after the disinfection processes.

- Change in resistance as a function of the storage period

- Optimal contamination methods for surfaces

- Influence of the substrate

One of the most important findings of the project was resistance modification by the addition of dimethyl sulfoxide (DMSO) to the sporulation medium of Aspergillus carbonarius DSM 872. This affected the melanin synthesis of the spores and thus, with an appropriate concentration of DMSO, the resistance of Aspergillus carbonarius DSM 872 could be matched to that of Aspergillus brasiliensis DSM 1988.

The following surrogate germs were identified by their suitable resistance, easy preparation and handling, and stable storage behavior under the various storage conditions, and are recommended as new test germs:

- Penicillium rubens DSM 848 for xenon flash.

- Aspergillus carbonarius DSM 872, modified with DMSO, for UV-C low-pressure or medium-pressure lamps.

These surrogates for Aspergillus species can be used for testing the efficacy of UV-based disinfection methods.

| Project term: | 2020 to 2022 |

| Project management/ funding: | Arbeitsgemeinschaft industrieller Forschung AiF (via Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. - IVLV) / Federal Ministry for Economic Affairs and Climate Action BMWK |

| Funding program | Program for the Promotion of Joint Industrial Research (IGF) of the BMWK based on the resolution of the German Bundestag |

| IGF Funding code | 20924 N |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV