Development of materials with specific properties

Materials with specific properties for use as packaging and technical applications

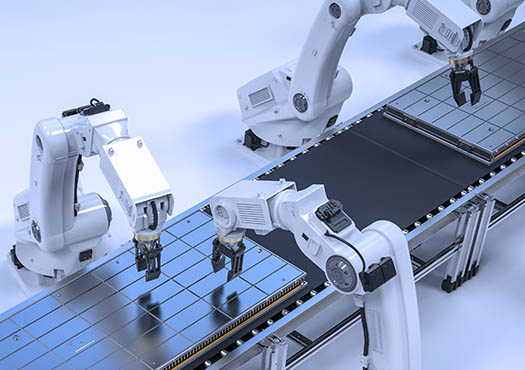

Due to their excellent and versatile properties, plastic films are valuable materials in various areas of application in the packaging sector. For example, they are used to protect sensitive food and cosmetics as well as highly sensitive solar panels and pouch batteries.

New holistic developments in terms of the circular economy are becoming increasingly important. The use of recyclable and recyclate-containing materials with the same protective function and food approval requires the development and use of innovative barriers.

We conduct research for you into functional barrier and coating technologies on films and surfaces, always taking into account the sustainable use of materials, as well as packaging materials made from monomaterials and the possible uses of recyclates.

The advantages of working with us:

- Access to national and international projects and the latest research results

- Design for recycling - development of recyclable materials and materials with specific properties

- Design from recycling - development of recyclate-containing materials through functional barriers with the aim of using them as food-compliant packaging

- Characterization of material properties

- Multifunctional surfaces: creating additional benefits for your technical applications

- Pilot production without production downtime: use our packaging pilot plant and save costs and time thanks to low material usage, high flexibility and fast results (we can produce and characterize initial film samples for you with just 1-2 kg of granulate)

- Scientific advice at all stages of development

Contact our experts

Design for Recycling

Are you still looking for a recyclable and cost-effective solution for your packaging materials?

We develop customized recyclable films for various applications - as packaging for food, pet food, pharmaceutical and cosmetic products, but also for the automotive, construction and electronics industries. We address specific requirements such as material reduction, recyclability, product protection, sealability, but also UV protection, scratch resistance and others for technical applications. We can also meet high requirements for barriers, e.g. against water vapor and oxygen, with our developments.

Design from Recycling:Plastics in the cycle

In various projects, we are investigating the effects of recycling processes on the mechanical and optical properties of films, as well as the changes in the processing behavior of various polymers with the aim of reusing recycled materials in films. Our research also includes the development of coatings to achieve food approval as well as the separation of individual components from multi-materials for recyclability.

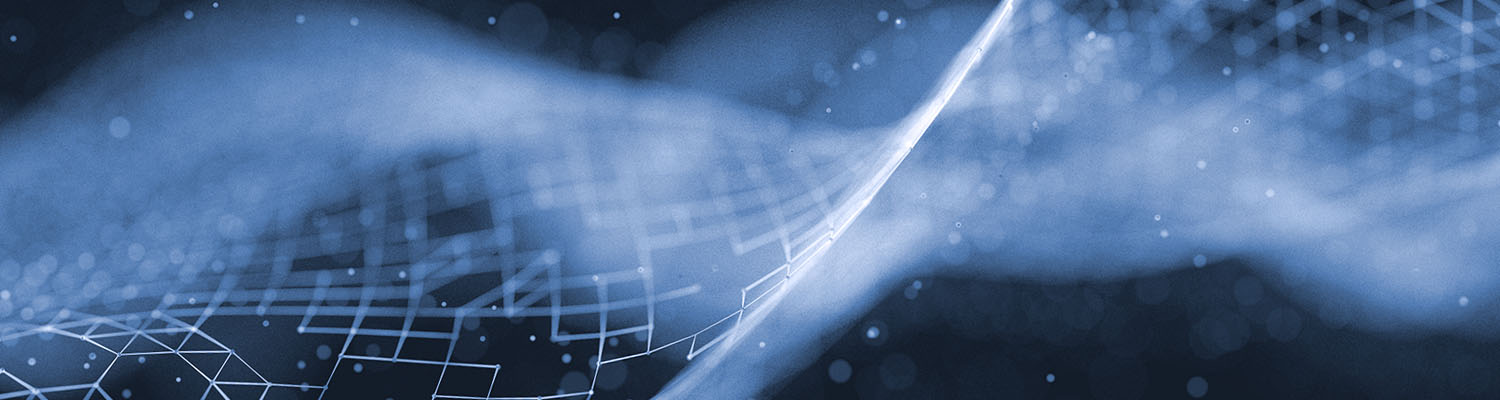

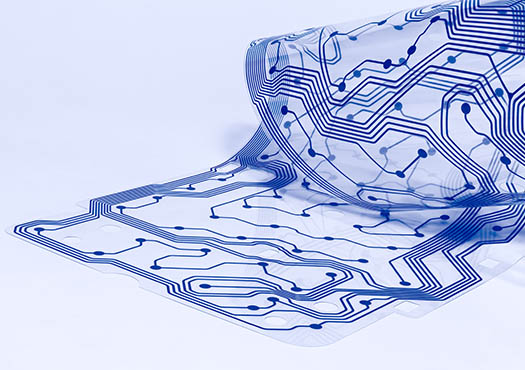

Functionalization of films and surfaces

Would you like to implement additional functions such as UV protection, anti-fog or printed electronics without using a lot of material?

We can support you with our expertise in the field of effective and large-scale functionalization of polymer surfaces in the nanoscale range, based on the specific application requirements of the overall system.

Coating developments for optimized properties

We improve the properties of web-shaped packaging materials in terms of their mechanical properties, processing behavior such as sealability and permeation. As a result, technical films achieve greater stability and quality. Our coating developments, modifications and scaling bring new solutions to the industry, whether on fiber or polymer-based substrates, for pet food, food, cosmetics, pharmaceuticals, batteries or solar cells.

Characterization and determination of material properties using microscopy techniques

New know-how or fluctuating material qualities?

We combine experience and analytics with an unbiased determination of specific product properties. We use a variety of microscopy techniques (optical microscopy, SEM, AFM, or Raman spectroscopy) to determine film thickness, roughness, composition, and the presence of defects. We also analyze mechanical and thermal properties, sealing methods and weld seams.

Our technical facilities and scientific expertise enable an iterative development of materials or the customization of your specifications.

Coating technologies for high-barrier applications

Our patented Spatial ALD system enables the deposition of high-quality coatings on flexible substrates. The roll-to-roll process takes place at atmospheric pressure and is characterized by conformal growth and layer thickness control at the atomic level. ALD coatings on polymers such as PET or PEN are virtually defect-free and can prevent performance loss in extremely moisture and oxygen sensitive products such as flexible electronic devices (e.g. batteries, sensors, flexible displays). The flexibility of our systems and our in-depth knowledge in this field make us the perfect partner for the development of new coatings in R2R configuration.

Use our unique pilot plants

Spatial Atomic Layer Deposition (S-ALD)

Our unique S-ALD plant is used for coating flexible substrates in a roll-to-roll process. The atomic layer deposition is performed in cycles in order to produce functional barrier films. A single atomic or molecular layer is deposited in each cycle. 3-D surface structures are covered uniformly with contour accuracy even at the nano-level.

Lacquering and laminating plant

Surface coating with water-based or solvent-based lacquers functionalises web materials according to requirements with gas barriers, water-repellent properties, UV protection and more. With subsequent lamination, we protect the sensitive functional layers with water-based or solvent-based adhesives. Thanks to the special film guidance of our coating and laminating system, even particularly sensitive high-barrier films that have been vapour-deposited with thin layers on one side can be further processed.

Use our lacquering and laminating plant for your pilot scale production

Vacuum coating plant

We use our vacuum coating plant to improve the barrier properties, conductivity, optical properties, and mechanical stability of flexible materials. The plant enables metals and oxides to be vaporized and then deposited on web-shaped substrates. These thin functional layers have a thickness in the nano-range and are applied to films and paper.

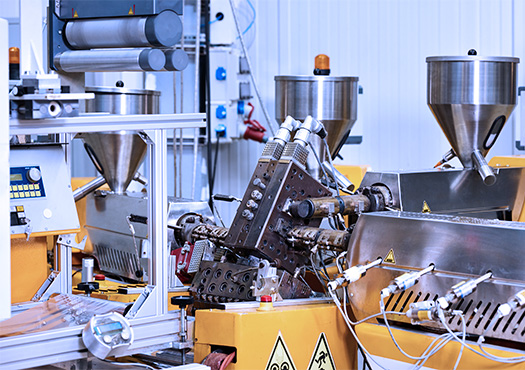

Extrusion and compounding

With our high-quality extrusion and compounding systems, we can test the functional properties of materials before they are used on an industrial scale. In our processing tests for plastics on a scale of 1 to 100 kg, we can also produce model products (polymer compounds, monofilms, film composites, thermoformed parts).

Optimize your materials using our extrusion and compounding equipment

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV