KoMMDia

Human-Machine-Dialogue as a Solution

Machines and installations for food packaging achieve technical efficiencies of over 95%. In everyday production, however, the Overall Equipment Efficiency (OEE) is lower, with only 60-90%. The reason for this are regularly occurring micro disturbances, i.e. short, constantly repeating interruptions of production, which have to be eliminated manually by operators. These frequent downtimes lead to high scrap rates, a reduction in production efficiency and staff demotivation.

According to the "Ironies of Automation" [1], increasing the degree of automation in production will not sustainably increase the OEE. Furthermore, the volatile and biogenic properties of the processed natural products complicate the sensory recording of all relevant parameters and make automation even more uneconomical. Therefore, KoMMDia pursues the alternative approach of human centration. The aim is to compensate for production variations between different shifts and increase the OEE of the packaging process by enabling the user to independently diagnose and eliminate disturbances.

[1] Bainbridge, L. (1983): Ironies of automation. Proceedings of the IFAC/IFIP/IFORS/IEA Conference. Elsevier, Baden-Baden. S. 129-135.

Research Approach in the Field - Application for the Industry

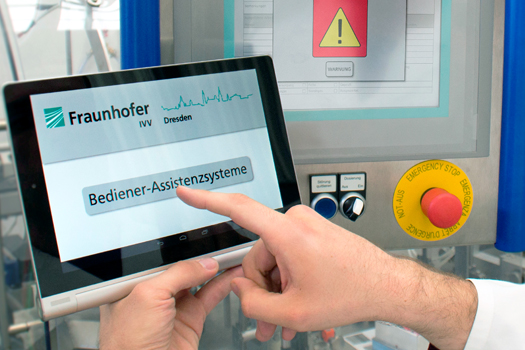

At the Fraunhofer IVV Dresden, a dialogue system and the corresponding components are developed together with research and industry partners.

Based on identified demands and wishes of potential customers and users of the dialogue system as well as psychological basic knowledge about communication processes and methods of knowledge extraction, concepts for dialogue design are being developed in the field of human-machine dialogue by the Chair of Engineering Psychology and Applied Cognitive Research at the TU Dresden. Empirical studies help evaluating and lead to an iterative adaptation of these concepts.

Using the case-based reasoning method, a Semantic Case Based Reasoner (CBR) is being developed by the Chair of Process Control Systems at the TU Dresden, which is used for case description and as semantic information environment for fault detection and diagnosis. A corresponding IT infrastructure will be established before domain-specific vocabularies and models for fault description are mapped in corresponding ontologies. Explicit operator knowledge is represented in the information environment by means of semantics to be developed.

Fraunhofer IVV Dresden is extracting high-resolution raw data sets from the available data sources of a packaging machine as part of the process data analysis, e.g. from the Manufacturing Execution System (MES), the control system and environmental data. The necessary interfaces are first analyzed and then created by ELCO Industrie Automation GmbH. The raw data sets can be examined for patterns using machine learning algorithms, which facilitates the selection of disturbances by the CBR system.

By using the CAD data of a packaging installation at Fraunhofer IVV Dresden, possible relationships between different disturbances can be predicted in virtual space during modelling and virtual commissioning. A virtual twin enables feature extraction and training of the machine learning algorithms in simulation prior to their practical use. The used models are from the industry partner and machine manufacturer Theegarten Pactec GmbH & Co. KG. Supplemented with an initial case base, the system can thus provide conclusive results more quickly.

The prototypical implementations of the components are subsequently combined in different demonstrator variants and evaluated both on a laboratory scale and under field conditions at the associated partners JR - Die Schokoladenfabrik GmbH and August Storck KG.

Further Project Information

| Project term: | 2017 to 2020 |

| Project management /project funding: |

Project Management Agency Karlsruhe (PTKA). – Production and Manufacturing Technologies /Federal Ministry of Education and Research |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV