Efficiency and ecological footprint — data gaps in the paper industry

In the last few years, paper production has become significantly more sustainable due to a continuous increase in the use of recycled paper. Nevertheless, it remains a resource-intensive production process. The dependence on a large number of different parameters, such as whiteness, ash content and tear resistance, also makes paper production highly complex. Since the process data from the individual stages of the value chain has never been linked together, there is a lack of comprehensive understanding of the cross-process interrelationships in the value cycle. As a result, it has not yet been possible to draw any conclusions from these interlinked processes, which prevents the adaptive real-time optimization of paper production.

So far, it has only been possible to optimize individual sub-processes for paper recycling, such as deinking or drying the paper. There has not yet been any recording or evaluation of the process data relating to other complex interrelationships, such as the highly variable composition and quality of the recycled paper used. However, these variations result in a significant increase in chemicals used in the production process, since determining the optimum quantity, while also ensuring the required paper quality, is not possible without a corresponding delay.

A self-learning assistance system for the needs-based optimization of paper production

In the ODiWiP research project, Fraunhofer IVV is focusing on the development of a self-learning assistance system for machine operators in the paper industry. The system will help operators to reliably analyze warnings and alarms, as well as deviations in quality, and to eliminate faults in the long term or prevent them by proactively intervening in the process before they occur.

For this purpose, researchers will analyze the formerly used process steps, digitalize existing practical know-how and develop software that will link and propose data-based information as required. Using machine learning algorithms, fault detection and fault prediction tools will be developed and integrated into the assistance system to achieve a high level of prediction accuracy. The system will provide relevant options for knowledge building, which can then be used to draw conclusions about the behavior of the interlinked processes.

The assistance system will enable machine operators to gain a better understanding of their processes and to respond to predicted or occurring faults efficiently and as required. The resulting reduction or prevention of downtime will result in an increase in overall equipment effectiveness (OEE) as well as operator satisfaction.

Paper production 4.0: linked process data for adaptive processes

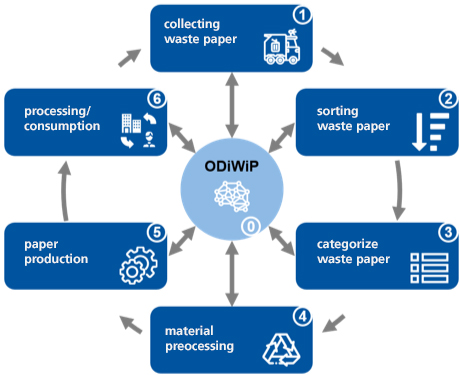

The overall ODiWiP project aims to use digital solutions to record the cause-and-effect chains of the paper production value cycle in their entirety, describe them across different processes, and thus enable targeted, comprehensive analysis and optimization.

Production processes can be made adaptive in future, which will have a significant impact on the increase in production efficiency and on the ecological footprint in terms of water and energy consumption.

Further Project Information

The research project “Optimized recycling cycle in the paper industry” is funded by the German Federal Ministry of Education and Research (BMBF). As part of the grant initiative “Digital GreenTech — Umwelttechnik trifft Digitalisierung” (Environmental Technology Meets Digitalization), this project is being conducted in the context of the BMBF’s “Research for Sustainability” (FONA) strategy.

| Project duration: | April 2021 to March 2023 |

| Project partners: | Consultingtalents AG, LEIPA Group GmbH, Chair of International Production Engineering and Management, Institute of Production Technology at the University of Siegen, Tomra Sorting GmbH, Papiertechnische Stiftung (PTS) |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV