InKraftSens

RESEARCH PROJECT

In the “InKraftSens” research project, we are developing a new method that uses thin-film sensors to enable near-real-time inline measurement and control of web force distribution in the production and processing of flexible fiber and plastic webs. The research results help to support companies in the legally required switch to sustainable, recyclable packaging materials.

Homogeneous web tension distribution is crucial to quality in the production and processing of flexible plastic or fiber webs. However, thin, low-complexity, natural fiber-based or recycled materials have more fluctuating properties and narrower process windows than established composites. Flatness deviations, wrinkles, inclusions and processing-induced stresses therefore have a far more critical effect. It is therefore important to detect such deviations as early as possible and react accordingly in order to reduce downtimes and rejects.

Conventional test methods such as Schmidt hammer or strip tests only provide results offline and on a random basis. Inline methods based on dynamic pressure or measuring foils/rolls can in turn lead to damage to the web. Optical methods, on the other hand, are subject to limitations with regard to printing and are relatively limited and expensive.

Conventional test methods such as Schmidt hammer or strip tests only provide offline and random results. Inline methods based on dynamic pressure or measuring foils/rolls can in turn lead to damage to the web. Optical methods, on the other hand, are subject to limitations with regard to printing and are relatively limited and expensive.

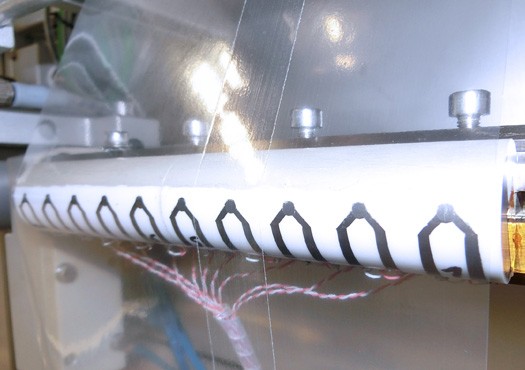

The novel inline measurement method developed in the research project uses the change in contact between the web and the measuring unit with varying web tension. This influences the heat flow from the temperature-controlled measuring unit into the web. Thin-film thermocouples are used to record the transferred heat in real time and with high resolution. This has already been successfully tested in the “RobInPro” research project (IGF 20340 BG).

The thin-film thermocouples are then attached to a web guiding element and provided with a suitable protective layer. This creates a space-saving and web-friendly measuring system that enables inline control of the web force distribution in real time.

The areas of application for this technology are wide-ranging, from the manufacture of technical products to the packaging of consumer goods and the finishing of flexible materials.

Additional project information

| Project duration: | October 1, 2024 - March 3,.2027 |

| Project sponsor/Grant authority: | Arbeitsgemeinschaft industrieller Forschung AiF (über Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. - IVLV) / Federal Ministry for Economic Affairs and Climate Action |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV