Double Helix Jet Cleaner

Tank cleaning nozzle with own DNA

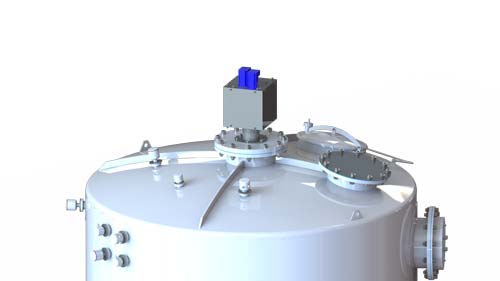

The Fraunhofer IVV Dresden has developed a novel jet cleaner suitable for all tank/container sizes that moves in offset helical paths starting at the tank/container top.

Jet cleaners have the most effective mechanical cleaning action and are suitable for heavy-duty cleaning tasks. The cleaning motion of current systems is, however, inefficient. This is because there is unnecessary repetition due to the overlapping motion pattern and the permanent back and forth travel of the jet.

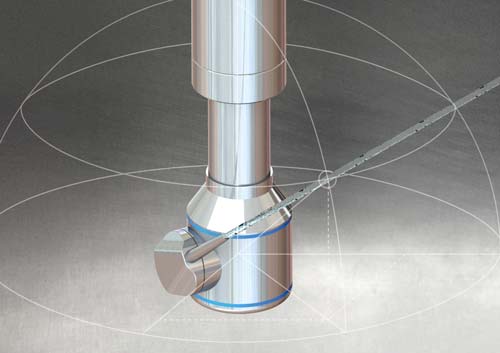

Procedure of Double Helix Jet Cleaners

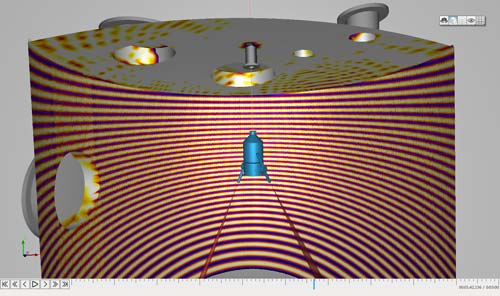

The double helix jet cleaner has an automatic reset function and so always starts cleaning in the center of the tank/container top. It travels in two efficient downwards-directed helical paths that are offset 180° to each other. The upwards swiveling nozzles are closed to the cleaning fluid.

If the cleaning intensity and path width of the double helix does not suffice for complete cleaning of the tank, a further cleaning cycle is performed. The nozzles then move in double helix paths offset by just 90° to remove any residual contamination.

Another major benefit of the helical cleaning path is the controlled discharge of contamination to the outflow.

Features of Double Helix Jet Cleaners

- Fluid-driven

- Cleaning from top to bottom in a double helix path

- Automatic reset function

- Optionally with four nozzles for more rapid cleaning

- Compact, robust, and no imbalance

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV