Hygienic production

Your competent partner for hygienic production and cleaning

Are you are faced with hygiene-related challenges with regard to your processes and machinery? Do you want to explore innovative ways of cleaning? Then get in touch with us, your competent partner for the automation of cleaning processes for hygienic production. Our development work on adaptive cleaning systems and their digital twin, as well as contamination sensors can help you introduce customized, highly efficient cleaning systems and processes at your company.

We assist you with the analysis and optimization of your cleaning processes. You therefore benefit from our experience and expertise in experimental and software-based simulation.

Furthermore, we are also your partner for the design and construction of special components and machinery for automated food processing and we have particular expertise in the area of hygienic design. We develop innovative concepts and support you right through to the commissioning stage.

Visit our cleaning technologies pilot plant in a virtual tour

Cleanability tests

We have developed a unique fluorescence-based inline system for detecting contamination which allows you to evaluate and visualize cleanability tests. Besides the before-after-comparison, spatially resolved monitoring of the entire cleaning procedure is possible. This enables determination of the cleaning time required for each point on a component. A customized test set-up helps to measure and visualize the benefits of newly developed hygienic design components/plants and can similarly support the design process.

Using mobile contamination sensors it is also possible to perform in-place analysis of the cleaning process in your production plants. During CIP (cleaning-in-place) we determine, for example, the extent of contamination in your tanks and using this data we optimize the cleaning processes with regards to cleaning time and usage of resources.

We perform microbiological validations to measure the effectiveness of your sterilization methods. Based on this we identify customizedl measures for process optimization and plant design. In addition we develop sterilization technologies precisely tailored to your products, packaging materials, and boundary conditions.

Our in-depth experience of cleaning technologies and microbiology can support you in all phases of your development work and production.

References:

Innovative cleaning systems

How many nozzles are actually necessary? At what angle to the surface should these be used? What type of nozzle is the most efficient? These are just a few of the many questions that need to be asked when developing a cleaning system. Even with a large amount of empirical knowledge the boundary conditions are very difficult to estimate. Using our expertise and unique technologies we can help you develop and optimize open and closed cleaning systems.

Benefit from our customized solutions for the robot-supported internal cleaning of your facilities (Mobile Cleaning Device) as well as for the cleaning of production rooms (see cooling chambers, cooking rooms). Just ask us! The systems are continuously being further developed to meet even the most difficult requirements in the future. For example, a multi-sensor system is currently being developed by us that will enable robots to find their way around complex environments even under the most adverse conditions (LocSens research project).

Besides innovative cleaning methods we use the latest design methods, including recently developed simulation software for open spray cleaning.

We increase the efficiency of your cleaning systems.

Contamination sensors

Industry is in agreement: Customized and adaptive cleaning processes require effective sensor systems. We develop customer-specific contamination sensors, for example based on the intrinsic fluorescence of the contamination or based on the shift of intrinsic frequencies due to the contaminants. These sensors are able to monitor the space and time resolved cleaning of large surfaces and to locally monitor specific contamination hotspots.

Our technologies enable you to monitor cleaning processes inline.

Adaptive cleaning systems

Would you like an alternative to your oversized cleaning process that wastes unnecessary time and resources because of its worst-case design? Our adaptive cleaning systems support you with the paradigm shift from empirical systems to model-based design, parameterization and control. Working with you we analyze your cleaning requirements, identify critical points and suitable sensor technology, and ensure that in the future the cleaning is performed in a need-based way with the help of an intelligent control system.

For this we have already developed a mobile cleaning device for processing plants and a revolutionary, directly controlled target jet cleaner. Should these systems or other available technologies such as robots be inadequate then we can develop a suitable special solution for you.

With our help you accelerate the digitalization of cleaning.

Cleaning systems developed by us:

Simulation of the cleaning

Cleanliness and safety are crucial in the food industry. The cleaning of food production, filling, and packaging plants is hence vital. Complex components and parts of machines, such as filling units in beverage plants, often present a challenge when designing cleaning systems.

For this reason we have developed innovative software for simulating spray cleaning. This allows the cleaning process to be visualized in real-time and determines the expected effectiveness of cleaning on complex surface geometries. It so facilitates the quick and cost-effective design of cleaning systems and saves lengthy, iterative optimization steps based merely on empirical knowledge. The simulation takes place in real-time and documents the cleaning tests of the selected system as a video. The software hence gives you a significant advantage for planning plants and for communication with your customers.

We use simulation to design your cleaning processes - resource-saving and efficient.

Automated processing

Do you have complex processes that are difficult to automate? Are you missing suitable components or assemblies for this? We gladly take on such challenges!

Working together with you we design customized solutions that are innovative, sustainable, and fully meet your specific requirements.

We are your partner for the development and design of automated processing modules and technical products. In line with our motto "form follows function", we combine technical functionality with hygienic design in all our development work.

We design processes for the future.

Examples of components we have developed:

- Hygienic hose gland for moving assemblies

- Adaptive Jet Cleaner (AJC):

- Mobile Cleaning Device (MCD):

- Hygienic elastomer grippers:

Hygienic Design

The hygienic design of machinery, plants, and components is vital in all industries where hygiene is important. Our experts work together with leading global associations such as EHEDG, 3A, GFSI and ENFIT and keep up to date with the latest guidelines and standards. We are thus able to assist you with the hygienic design of your machinery, plants, components, and production environment.

We can, for example, assist you with:

- Evaluation and optimization of components and plants with respect to their hygienic design, e.g. EHEDG Document No 8/13 or GFSI Benchmarking requirements (v2020) Part 3 Document J1/J2.

- Identification of optimization measures and development of sustainable solutions

- Design aspects and support through the development process

- Evaluation of the production environment according to HACCP

- Drawing up action plans and support with their implementation

With our help you can create a hygienic production environment.

The new EHEDG cleanability test

The new test allows equipment and component manufacturers to evaluate thei machine and plant designs based on EHEDG standards early in the development process.

View Max Hesse presenting the test at the EHEDG Online Expo 2021:

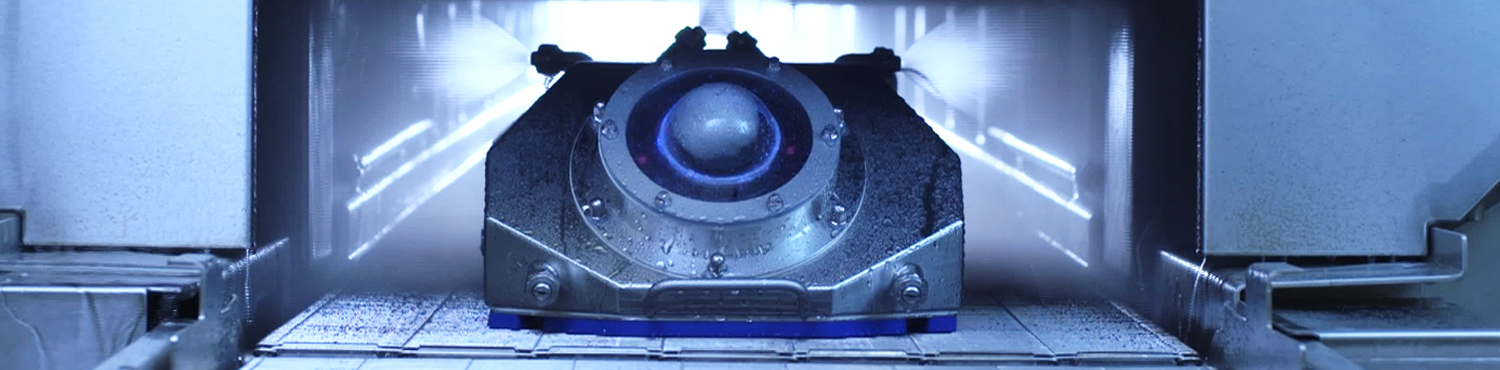

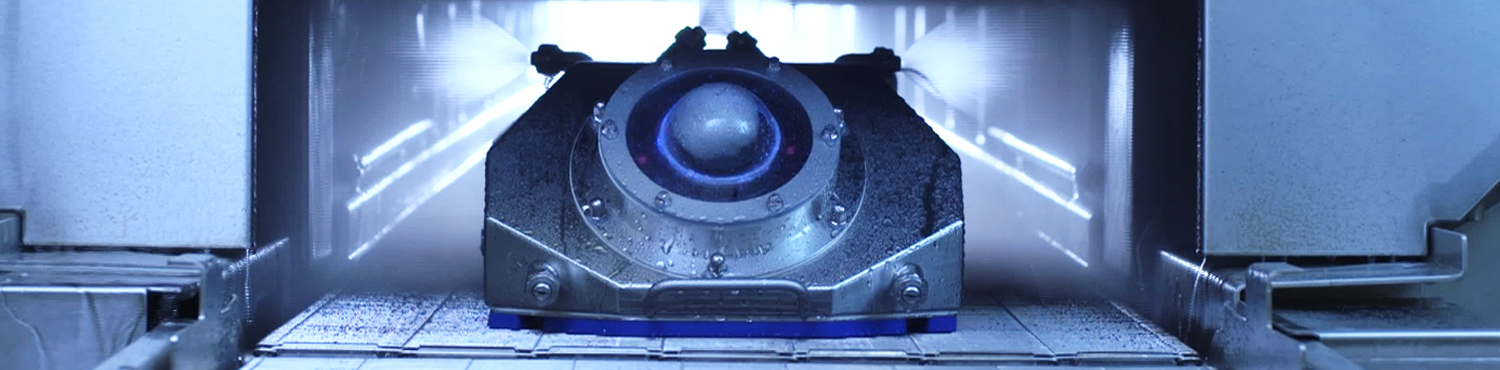

Test and Development Center Component Cleaning

Our Test and Development Center Component Cleaning offers you know-how and equipment for carrying out reproducible cleanability and cleaning tests and for testing and optimizing innovative cleaning processes.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV