2K sandwich injection molding for packaging: Use recyclate, maintain product quality

The packaging industry, with its high plastic consumption, contributes significantly to CO₂ emissions. To counter this, the European Packaging and Packaging Waste Regulation (PPWR) mandates a substantial increase in the use of recyclates. Meeting this requirement is particularly challenging in hygiene-sensitive sectors like the food industry, where fluctuating material properties and potential contamination of recyclates conflict with strict safety and hygiene standards.

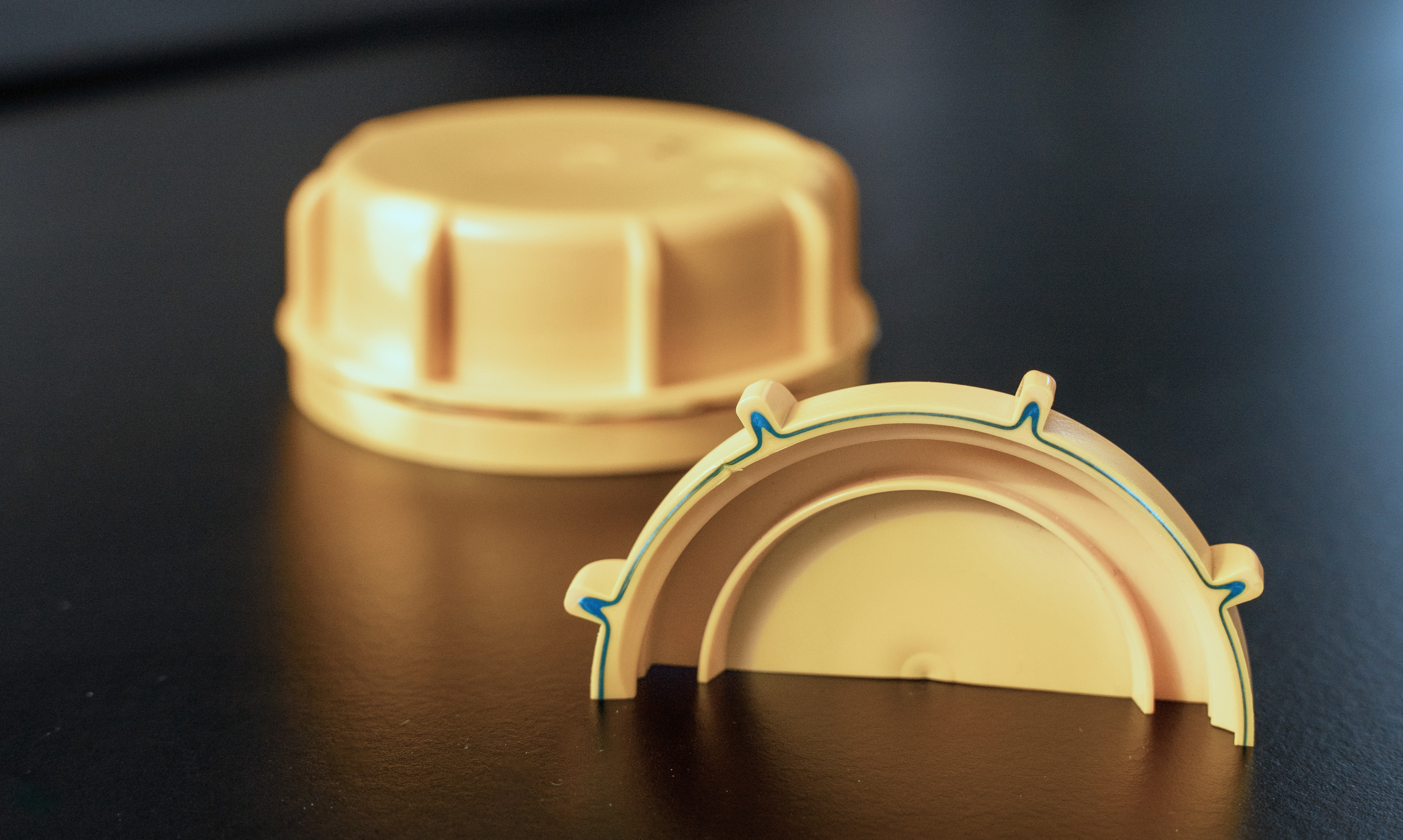

A promising approach is the targeted combination of virgin and recycled materials using 2-component injection molding. This process allows two different materials to be combined within a single, integrated production step, enabling recyclate to be used as a core material while enclosing it in virgin material to avoid direct product contact.

To ensure the recyclate is fully enclosed and accurately positioned, machine parameters - such as dosing volumes, injection speeds, and phase transition points - must be precisely controlled. Depending on the geometry of the molded part, these settings are crucial to achieving the desired distribution and location of the recycled content.

The challenge of melt flow with recyclates

Recycled materials often show altered melt flow behavior due to inconsistent material composition and varying additive levels. In 2K injection molding, this can cause the core material to break through the outer skin layer, negatively affecting product quality and functionality. Precise process control is therefore essential to ensure correct placement of the core material and to prevent such breakthroughs.

In this research project, a tool equipped with integrated pressure sensors was developed for inline monitoring of melt flow behavior. This enabled the detection and analysis of viscosity differences between the two components. In parallel, optical inspection of the molded parts was conducted to assess quality.

Intelligent assistance for optimum operating parameters

Using physical modeling and statistical analysis of process data, the complex interdependencies between system parameters were simplified and narrowed down. Key process variables were transformed into a parameter space defined by dimensionless, independent variables.

Based on this, an interactive assistance tool was developed to support operators in selecting suitable parameter combinations and to directly visualize the impact of parameter changes. This led to significantly more stable process settings and a 30–50% reduction in setup time.

Do you have any questions, or would you like more information about our research project? Feel free to contact us!

Further Project Informationen

| Project duration | June 1, 2023 - December 31, 2024 |

| Cooperation partners | A&E Produktionstechnik GmbH, BERGI-PLAST GmbH |

| Project sponsor/Grant authority: | BMUV (DigiRess) |

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV