Web transport of flexible materials

We can help you improve the quality of your production process.

You are most welcome to contact us!

Importance of effective web transport

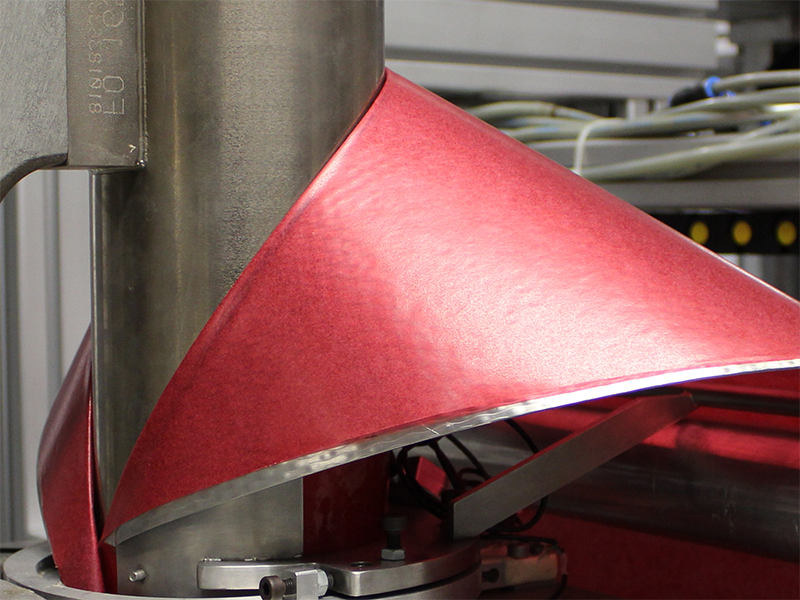

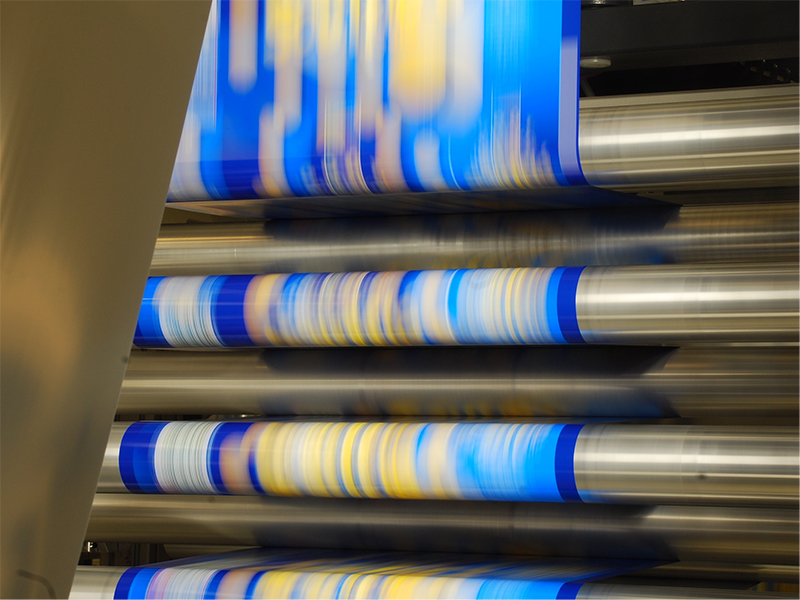

The web transport test rig uses the rewinder principle and comprises unwinding, measurement/testing, and winding sections. It allows defined processing conditions to be set. Controlled unwinding comes after a controlled dancing roller system in the form of a web buffer. Selecting the tension of the buffer allows the winding of the web to be performed under defined winding tension.

In the measurement/testing section, the processing and measurement of the web tension / web tension profile are performed. Testing different machine components is made possible by the flexible web transport, separate drive system, and large assembly space.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV