Self-learning assistance systems

for machine operators

Assistance systems for machine operators

The efficiency of processing machinery often depends on the experience of those people operating the machines. The classic exchange of knowledge via (digital) documentation is virtually impossible in real production environments. A reason for this is the time-consuming search for helpful information in the event of a fault.

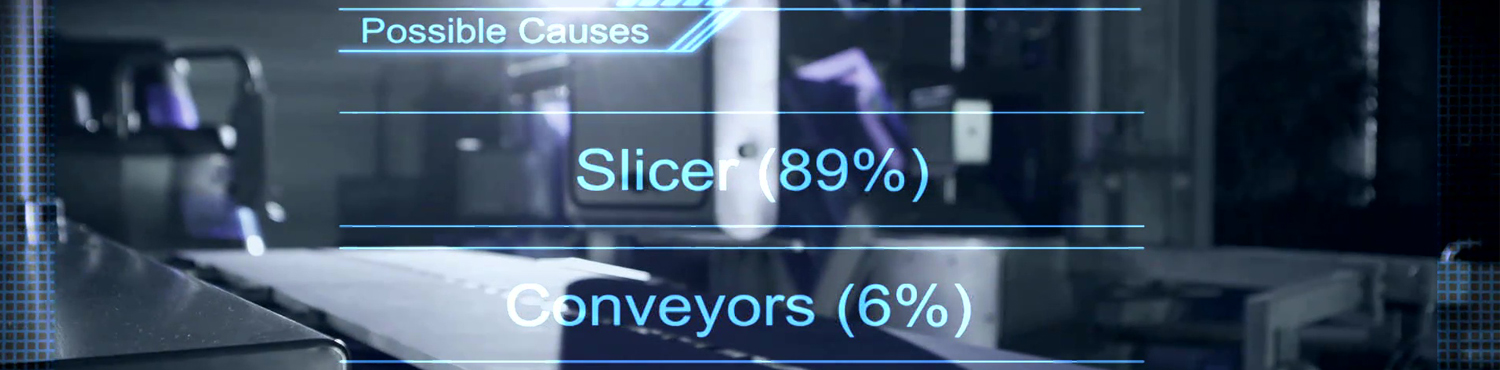

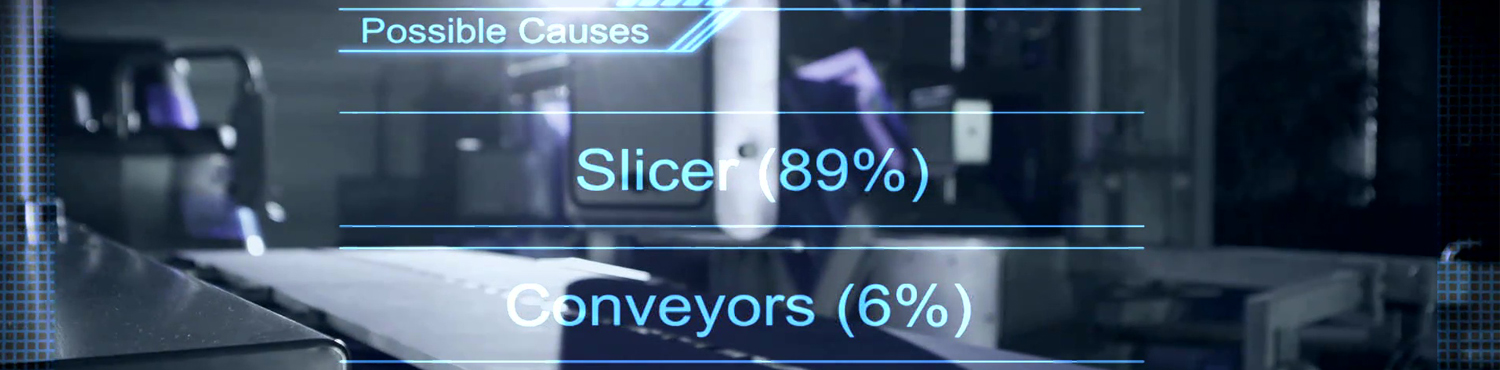

In order to solve this problem we have developed a self-learning assistance system for machines (SAM). This software combines machine learning with human experience in order to reduce production downtimes. Algorithms enable SAM to independently learn events from process data from the machines. Recognized machine states are linked with operator entries in a database. Compared to a standard error message, users are given a far more precise solution based on "machine learning" which via a tablet enables rapid access to potentially useful entries.

Improved production efficiency

By providing targeted support for machine operators, faults can be permanently rectified. The number of rejects, the operating time, and the manpower requirements can be reduced by our assistance system with a simultaneous increase in production capacity. The production efficiency is higher.

There is also better production planning due to the fact that production difficulties are vastly reduced and in the best case avoided. Hence delivery problems and extra costs due to transport delays and having to re-plan do not arise.

Improved planning and employee motivation

SAM is an exchange platform for operators, technicians, and engineers and is a type of "virtual colleague" following the principle of on-the-job-training. The Fraunhofer IVV Dresden works closely with psychologists and professional UX/UI experts in order develop software having the highest acceptance amongst users in proband tests. This enhances the involvement of employees and their motivation to contribute their own ideas and solutions. The latter benefit the whole system.

SAM helps you design processes more efficiently in the short term and also tackle longer-term challenges such as employee turnover, a shortage of skilled workers, and demographic changes.

SAM in detail - How our operator assistance system works

With our self-learning operator assistance system for processing machines SAM, we offer situation-adapted and individual solution strategies for your processes.

With standard knowledge memories for machine operators, the manual search for helpful entries is problematic and time-consuming in the event of an error. Different designations, spelling mistakes or time pressure make targeted, efficient searches difficult, even in digital archives with full text search. Therefore, the motivation to maintain and expand the repositories is limited and the overall acceptance of the employees is rather low.

SAM is dedicated to this challenge and, for the first time, independently searches for suitable solution proposals for the present error case in the database. The special feature lies in the ability to learn new error cases and to recognize them independently. Algorithms of machine learning are the basis. By analyzing the machine-internal sensor data, for example switching signals from light barriers, incidents can be perceived much more precisely than was previously possible with fixed programmed error queries. Interaction with the operator takes place via a mobile device or a PC.

FAQs - the most important questions and answers about SAM

A selection of commonly asked questions about SAM.

How are the operators encouraged to input their knowledge?

Many people are motivated by recognition, which is the basis of forums and, for example, Wikipedia. Better utilization and variation of entries and public appreciation motivate those with long experience. This has been shown in numerous discussions with operators. We also work closely with psychologists and UX/UI designers to enable us to optimally adapt to the wishes and requirements of users.

How does SAM differ from normal logbooks and knowledge bases?

SAM learns to recognize fault conditions and automatically presents suitable suggestions from its knowledge database. Algorithms of machine learning help to more clearly differentiate between fault conditions than is currently possible via, for example, machine error codes. As such, the unique analytical capabilities of people are mimicked.

How is SAM connected to the machine? Can SAM interfere with the machine?

Our operator assistance system is connected to an autarkic PC system via a universal interface card with the field bus of the machine. SAM controls (SPS) the machine as a "slave". It receives high resolution, non-processed and processed SPS data, for example sensor switching times. This corresponds to the basic principle that SAM cannot actively intervene in the process. It is purely a support system that offers options. The user still makes the decisions.

What data does SAM receive and where is the empirical knowledge stored?

In its simplest configuration SAM has no Internet connection. Users always have full control of the generated data because the trained models for recognizing faults and the existing knowledge bases are stored on the computer on the machine. Connecting several SAMs at a work location or worldwide can however have enormous advantages. The customer always decides which system is favored.

Become a pilot customer

Get involved as a pilot customer or as a member of our advisory group

For rapid and efficient development work to meet the needs and requirements of industry it is vital to involve partners from industry and R&D organizations. We are therefore forming an advisory group consisting of machine operators and machine manufacturers. Please get involved!

Contact us - and learn about the many benefits of collaborative R&D.

Events

We regularly present the latest developments and trends from the fields of digitization and assistance systems:

November 6th - 7th, 2024 - Fraunhofer IVV, Dresden

"Future Days: Applied Digitalization in the Food Value Chain".

(Event language German)

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV