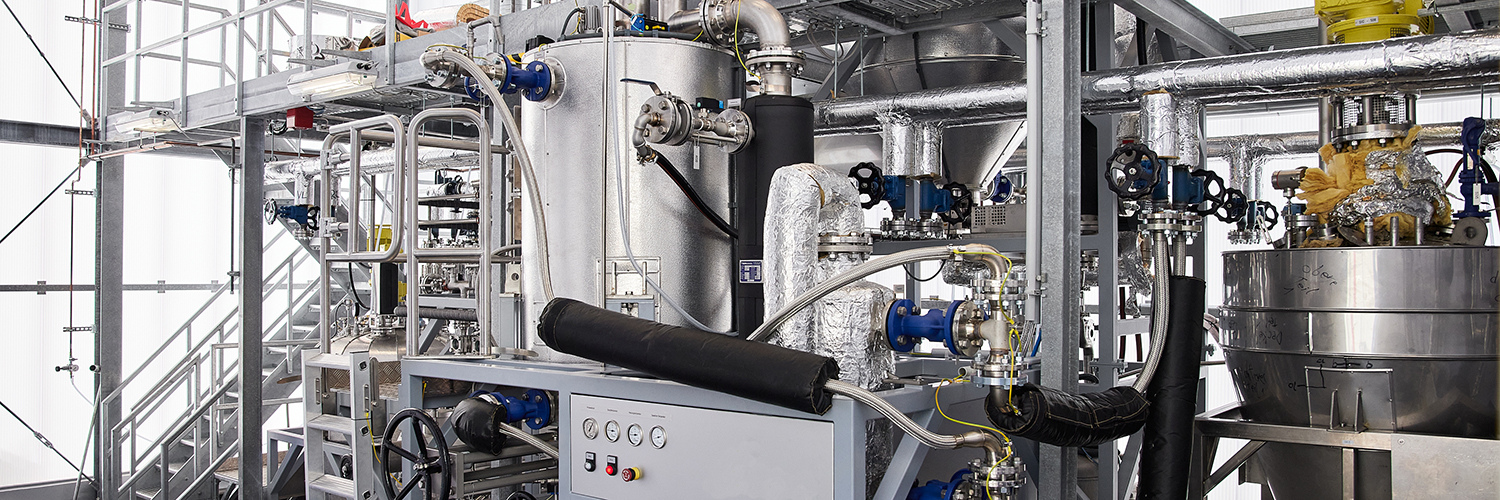

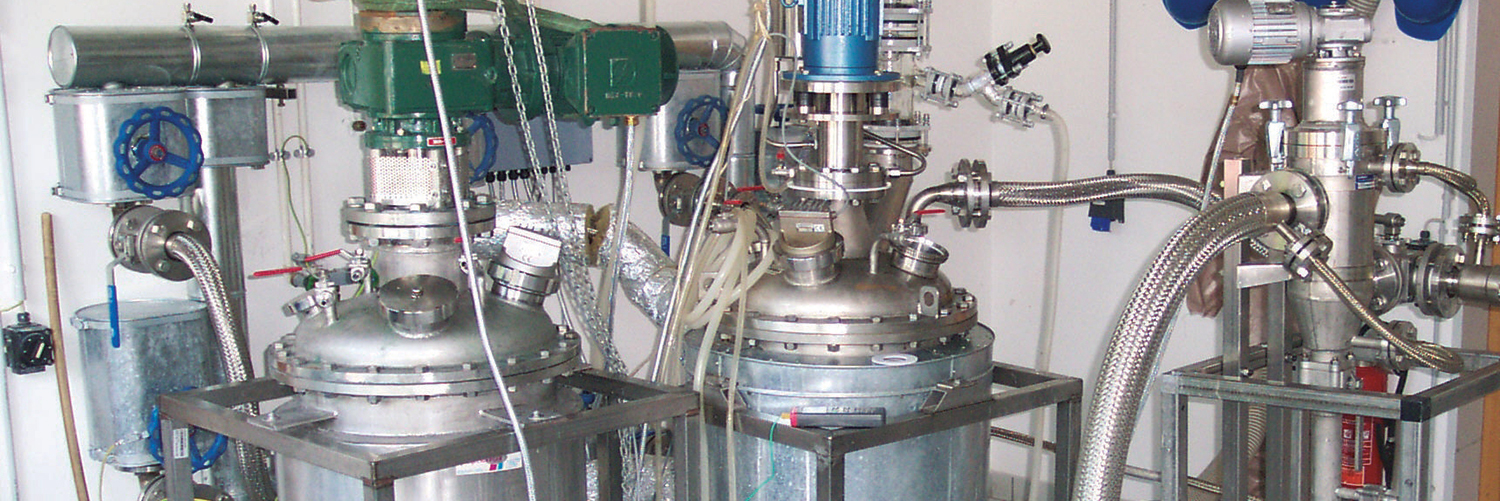

In our pilot plant we develop customized recycling processes

We work primarily on solvent-based plastic recycling processes with particularly high purification potential. We offer interested companies a close cooperation to adapt our basic process to specific target polymers and waste fractions. At the Fraunhofer IVV, we accompany the process adaptation up to the technical scale, together with plant engineering companies even up to commercial implementation.

As a first step, we carry out a feasibility study on a laboratory scale. We then use the data obtained to scale up to a small technical scale before moving on to the demonstration scale (TRL 6) in our large-scale pilot plant. In all three phases, in addition to sample production, the investigations focus on increasing the quality of the recyclate and process economy as well as testing suitable aggregates.

We use the product samples obtained in the three development phases as well as mass and energy balances as a solid basis for reliable economic feasibility studies.

Fraunhofer Institute for Process Engineering and Packaging IVV

Fraunhofer Institute for Process Engineering and Packaging IVV